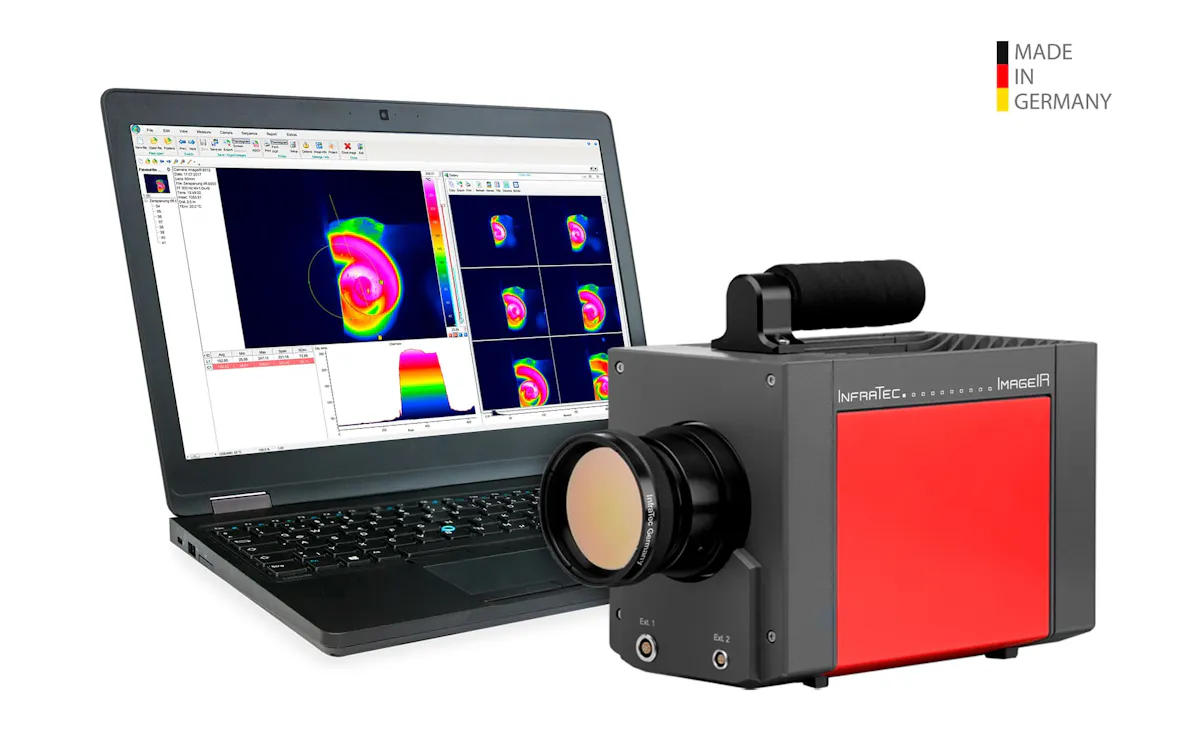

High-end Camera Series ImageIR®

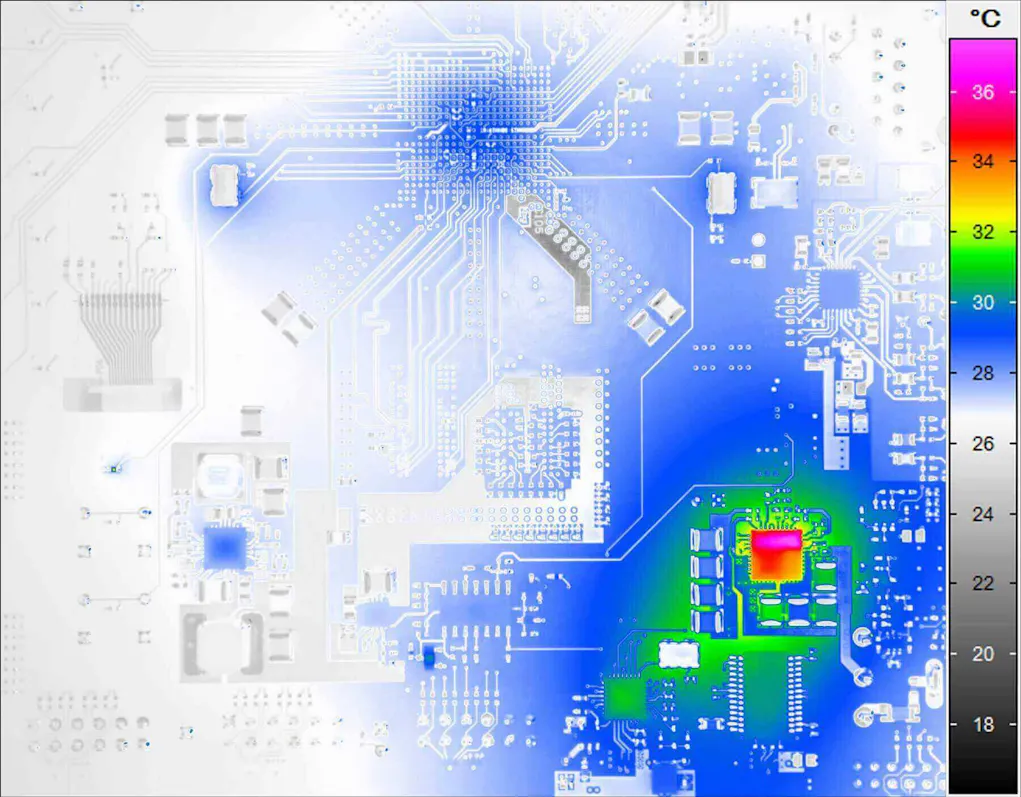

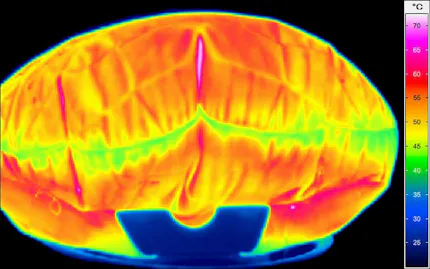

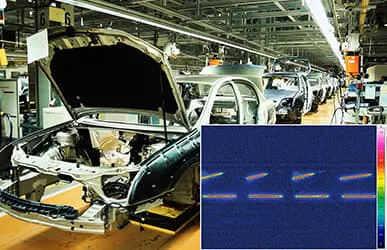

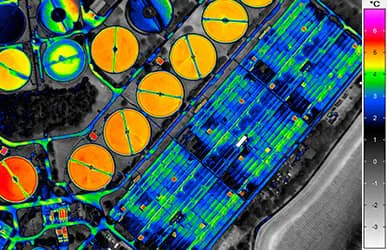

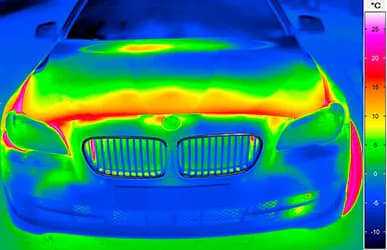

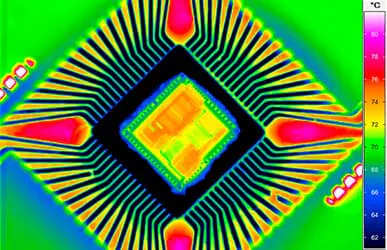

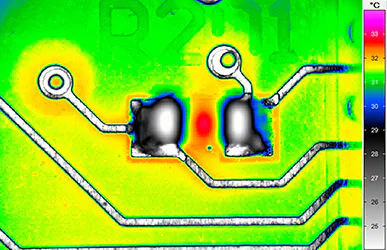

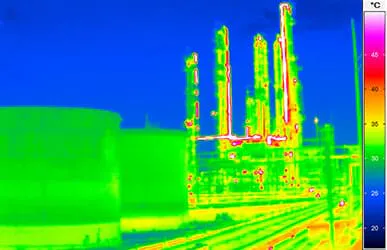

The high-end thermographic cameras of the product series ImageIR® from InfraTec meet the highest demands in research and science, for non-destructive inspection as well as for process control. The modular concept enables excellent adaption to your specific measurement and inspection tasks. Cooled photon detectors of different types (InSb, MCT), spectral sensitivity ranges and formats are used. The numerous equipment options include powerful infrared full optics, filters and rotating aperture wheels, trigger and data transfer interfaces as well as motor focus units suitable for continuous operation.

Spatial resolution with detector formats with up to (1,920 × 1,536) infrared pixels

Integrated into camera, genuine temperature measured values

Precise detection of smallest temperature differences

Due to Binning technology increase frame rates and thermal resolution at the same time

Analysis of high-speed dynamic temperature changes and processes

More flexibility for upgrades and changes of components

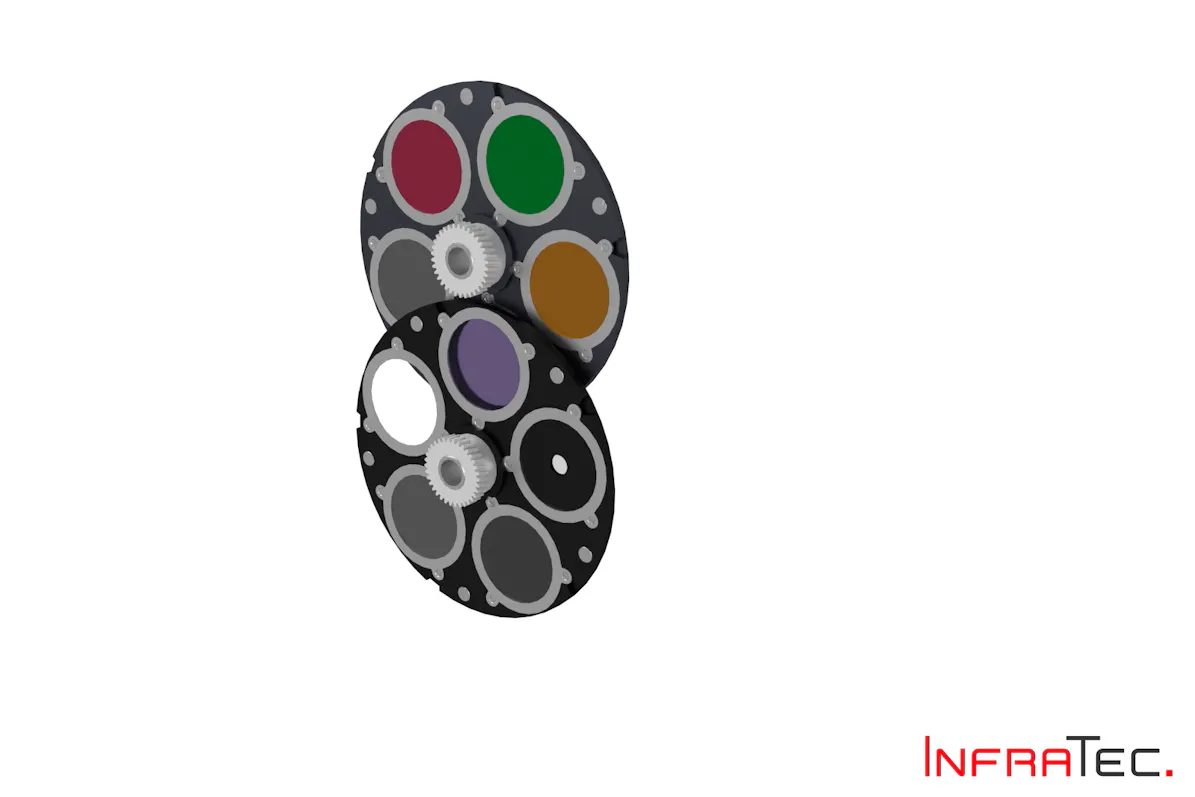

Flexible filtering by inbuilt two filter- / aperture wheels with up to 25 combinations

Precise triggering with only 10 ns jitter

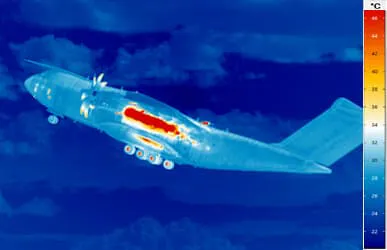

Infrared Zoom Camera Series – High-end Cameras with a Long Range

The radiometric infrared zoom cameras from InfraTec enable the detection of smallest objects and measurement of their temperatures even over long distances. With their various technical features, they are suitable for measurement tasks in research & development or quality assurance as well as in the field of security applications, e.g. for surveillance tasks.

ImageIR® 6300 Z

Small, lightweight, radiometrically calibrated and versatile in use

ImageIR® 8300 Z

Super-zoom infrared camera series with (640 × 512) IR pixels

ImageIR® 9300 Z

Super-zoom infrared camera series with (1,280 × 1,024) IR pixels

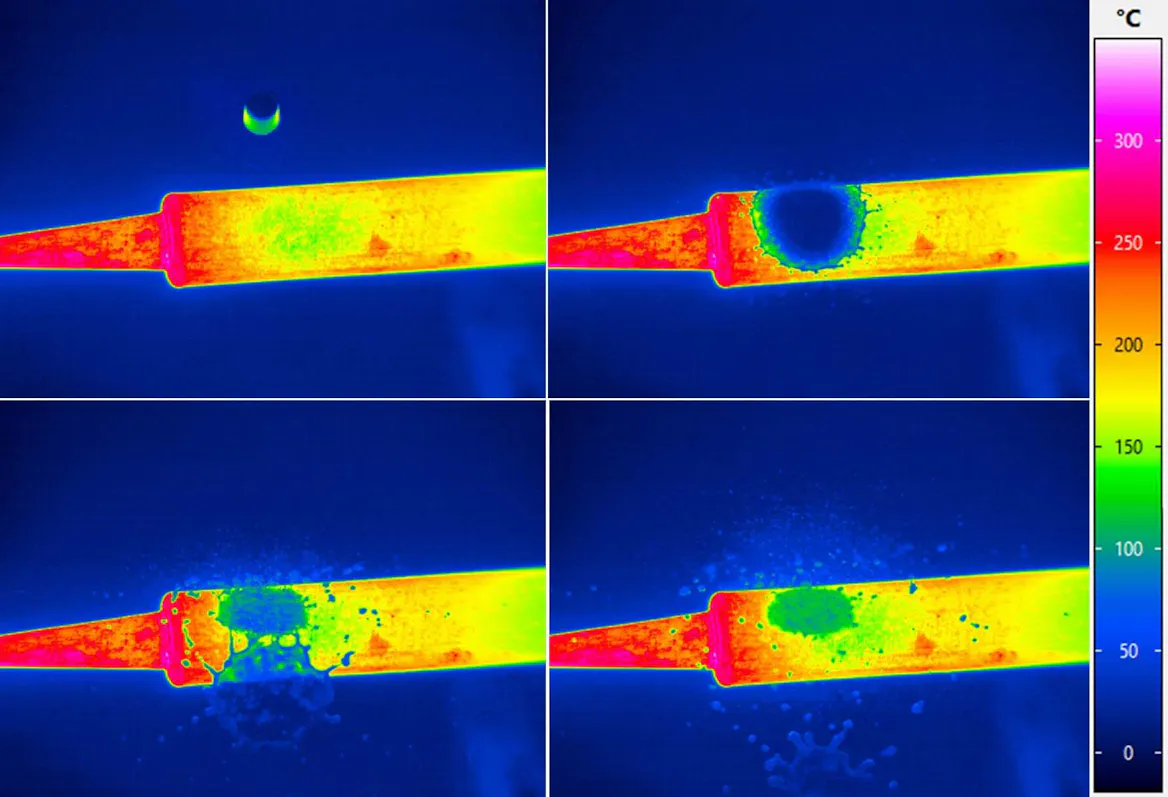

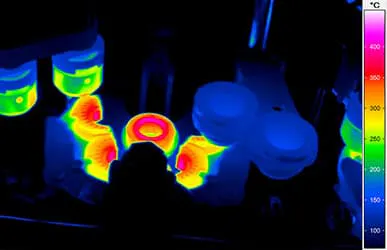

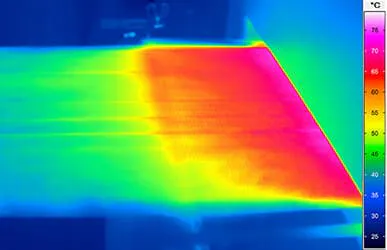

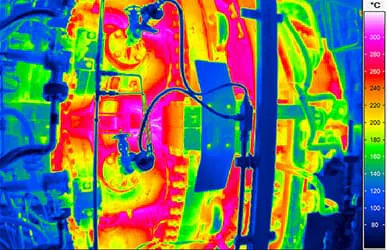

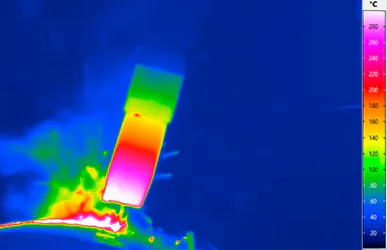

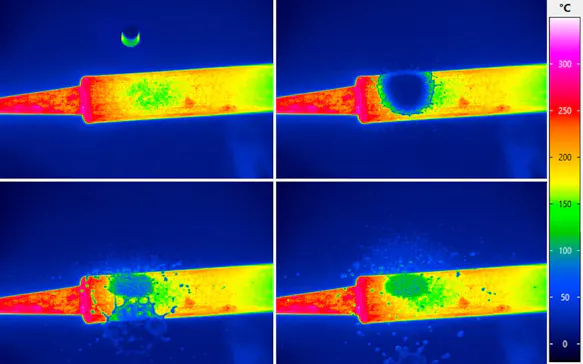

SWIR Infrared Cameras – High-resolution and Radiometrically Calibrated

The SWIR infrared cameras from the ImageIR® series are high-resolution, radiometrically calibrated infrared cameras that operate in the short-wave infrared (SWIR) range. They have been specially developed for thermographic measurement tasks characterized by very high temperatures and challenging materials. For example, they allow emissivity-optimized measurements of temperatures on metallic surfaces – in high-temperature ranges between 300 °C and 1,700 °C. Further areas of application can be found, for example, in additive manufacturing and laser applications or in the metal industry in the field of welding processes or press hardening.

ImageIR® 8100

Radiometrically calibrated with (640 × 512) IR pixels

ImageIR® 9100

Radiometrically calibrated with (1,280 × 1,024) IR pixels

InfraTec ImageIR® High-End Infrared Camera Series

You Need More Information about the ImageIR® Camera Series?

There is a ImageIR® matching perfectly your specific requirements. To find out which one it is, just check out all the models in detail.

Innovations for Precise Performance

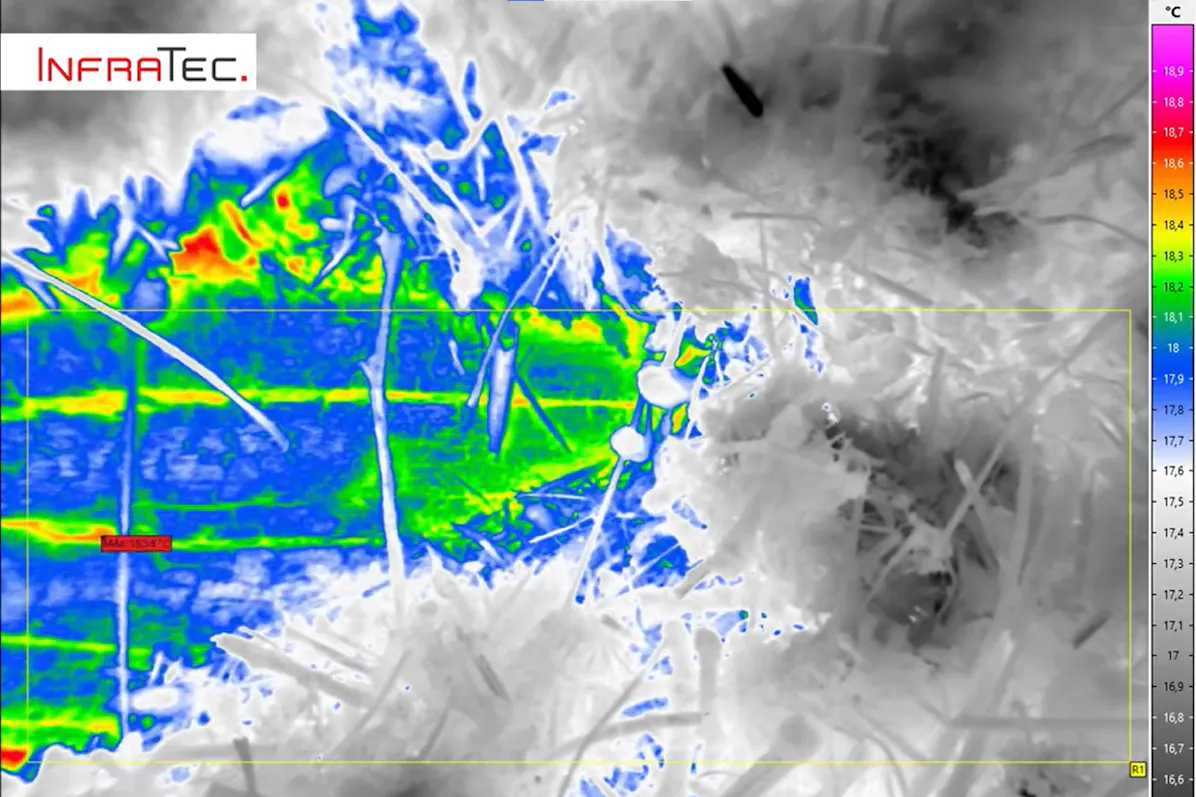

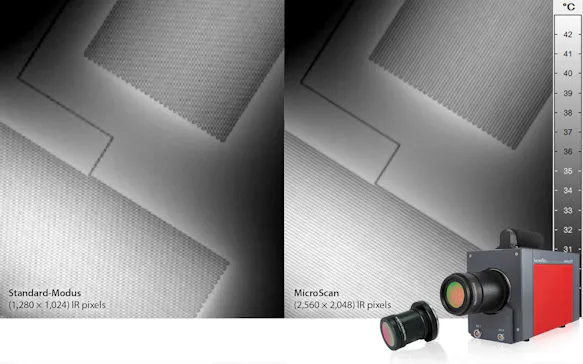

MicroScan – Quadruple the Image Format

Behind the function is a fast-rotating MicroScan wheel, which is integrated into the camera. It ensures that four different individual exposures are taken per wheel revolution, which are offset laterally by half a pixel each. These individual exposures are brought together in real time into a thermogram with quadruple image format. Each pixel in the image represents a genuine temperature measured value and not an interpolated image point. In this way, thermography achieves a new quality due to thermal images providing a spatial resolution up to 3.7 Megapixels.

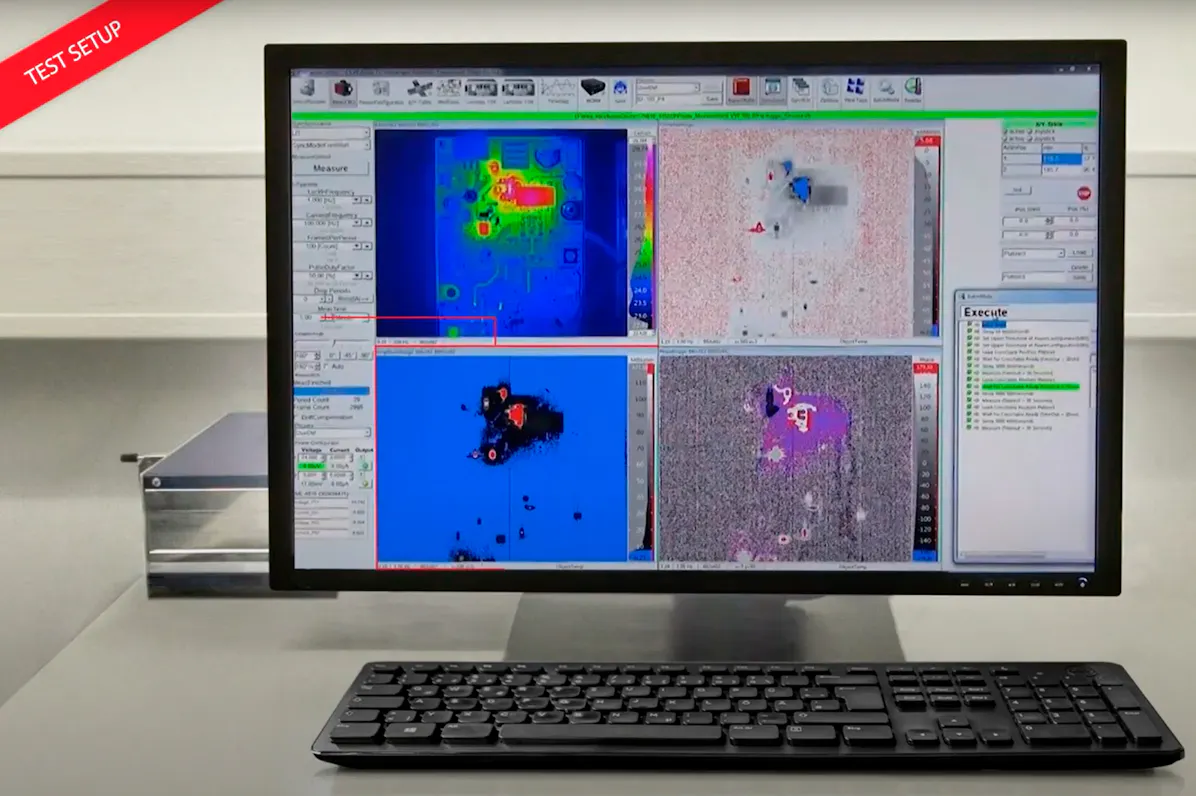

High-speed Mode – Increase Frame Rates and Thermal Resolution

If you want to analyze the thermal behavior of objects and processes from a wide variety of perspectives, you can use the high-speed mode for maximum flexibility. This function allows the camera to be used in two different operating modes. The standard mode suits best for depicting the smallest geometrical details. This allows users to record images with the native number of pixel of the camera detector. Switching to high-speed mode opens up the option of more than triple the frame rate, while the field of view (FOV) remains identical. This enables for most accurate time monitoring of fast processes. At the same time, the thermal resolution increases by a factor of 2 in high-speed mode, which additionally improves the analysis of temperature differences.

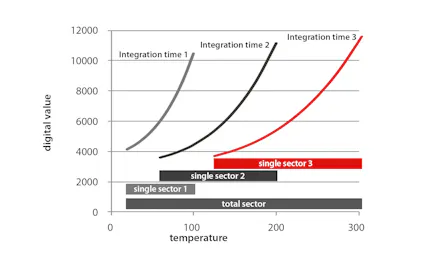

Download HDR Whitepaper

Download the HDR white paper to get further information how it works and what the benefits are.