Sensor News

In the Sensor News you will not only get information about innovations and events at InfraTec, but also exciting insights into the wide range of applications of InfraTec's detectors when our customers report. That's why it's also worth taking a look at the archive.

Read in the Current Issue

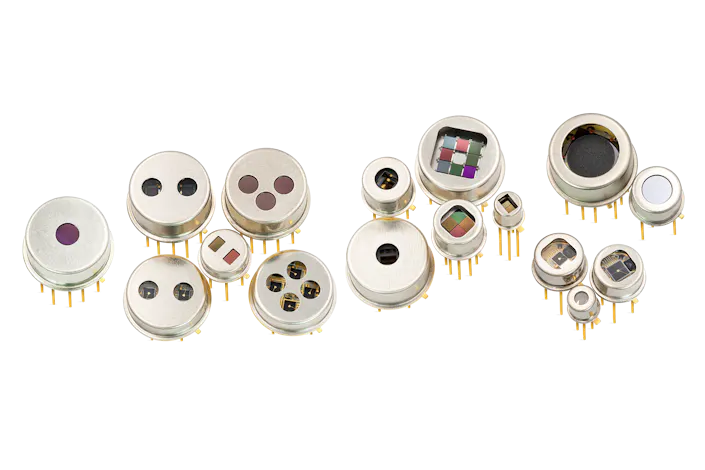

Success Story: Leak Detective in Action For More Safety

Success Story: Special Detector For Fuel Analysis

Nothing Remains Undetected - The PYROMID® LRM-292 For Your Safety

InfraTec – Always in Action

InfraTec – Always in Action

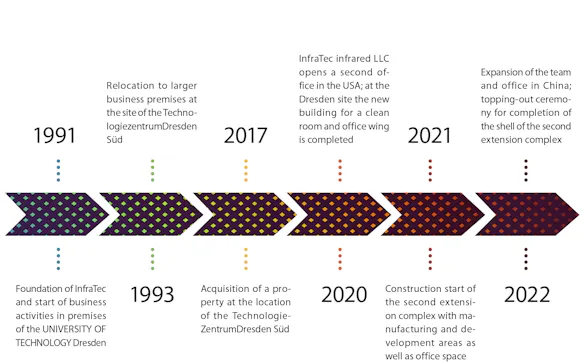

From the „production laboratory“ in the basement of the former kindergarten of the Technical University of Dresden to the opening of the first real clean room, InfraTec developed into a powerful high-tech company. To date, InfraTec is growing not only at its headquarters in Dresden, but also worldwide through its subsidiaries. In 2007, for example, InfraTec infrared LLC was founded as a subsidiary of InfraTec in the USA, and in 2012 a representative office was established in China.