Case Study: Inline Process Control for Quality Assurance of Weld Seams

Miscellaneous welding tasks in steel constructions currently have a low degree of automation, resulting in a high amount of manual work and employee-dependent quality levels. As part of the 3dStahl collaborative project, a 6-axis robot, equipped with a welding machine, was attached upside down to a wall-to-wall wire rope hoist kinematics system in order to automate joining processes involving small quantities or even individual parts such as large-scale objects (lock gates, bridges). Fast 3D sensor technology provides three-dimensional data for defining the welding area. This data is used to position and track the welding robot. The continuous process quality assurance is achieved in parallel by means of an infrared camera and a multi-spectral camera system.

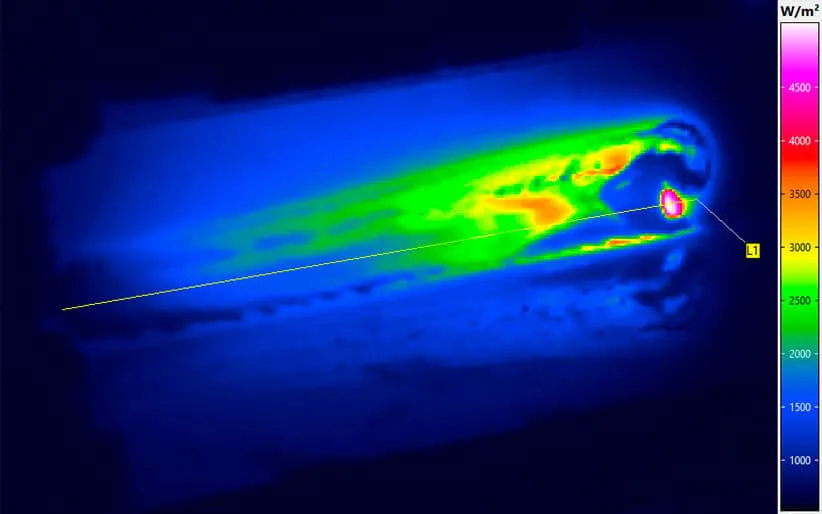

The infrared camera detects the emissivity change and intensity distribution of the infrared radiation emitted by the resulting weld. The intensity is the specific radiation in W/m², meaning which power is radiated from the measurement object per area. The measurement of the absolute weld temperature is only possible to a limited extent due to the reflective properties of the metal material and variable emissivity associated with the weld molten mass. Nevertheless, in-line process control is possible and influencing welding parameters can be derived by examining relative intensity changes within the measurement series using the measurement instrument.

Test Object

For the analysis, two steel sheets are placed in a T-joint, so that one part hits the other vertically with the front. The resulting fillet weld between these sheets is examined during the process.

Read more about inline process control with infrared camera VarioCAM® HD head 800