Thermographic Inspection of Photovoltaic Installations

An infrared camera helps to visualise defects on new and existing installations

Efficient method for detection of power losses

Detection of a wide range of local faults and irregularities

Visualisation allows initial on-site evaluation

Plant system condition monitoring over time with stored data

Application in running installations

State-of-the-art thermographic software for efficient reporting

Thermographic Cameras For Use on Wide Variety of Photovoltaic Installations

Over the last years a remarkable increase of photovoltaic installations for producing renewable energy with both residential and non-residential buildings could be registered. At the same time large solar power plants were installed for using the sun’s energy. In the next years the use of renewable energies will become increasingly important.

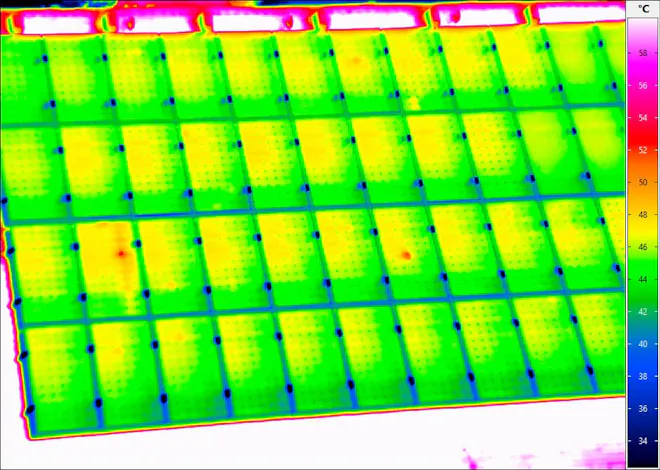

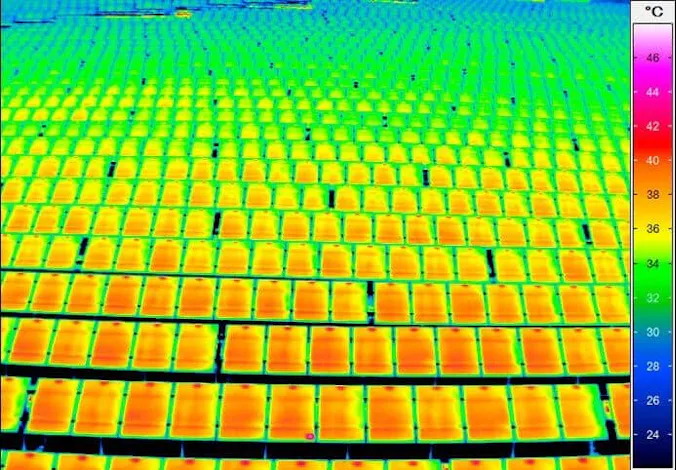

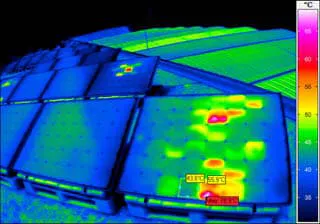

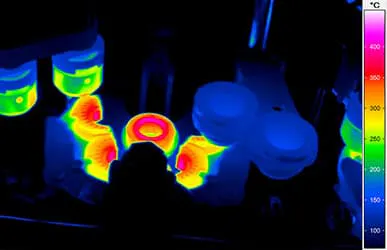

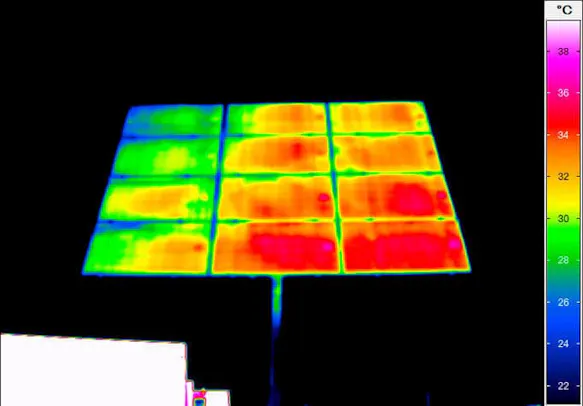

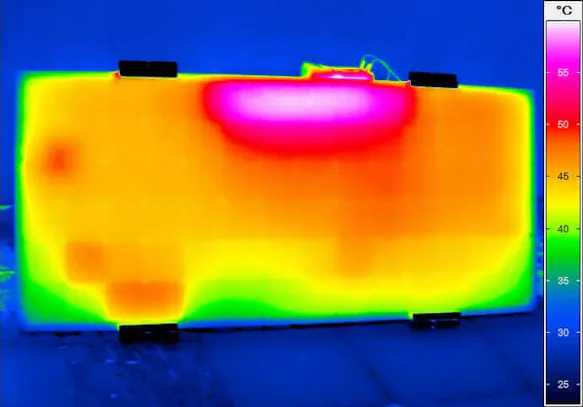

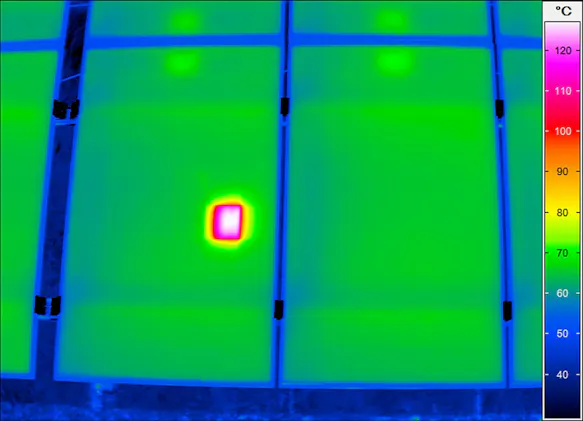

Over the time many installations are losing part of their initially installed power which leads to a decrease in energy yield. Single cells break down, important components such as inverter do not operate at their maximum efficiency. As a consequence - besides reduced yields - warming and overheating of local faults caused by parasitic currents can cause further damage to the installation and finally lead to fires, too. Using thermal imaging, these faults - also named hotspots - can be located easily due to their thermal signature and subsequently be repaired targetedly. Due to the variety of manufacturers of photovoltaic installations that are in use today, a multitude of defects can show most diverse geometry and appearance. A prerequisite for reliable fault detection is the use of thermographic cameras with outstanding features as well as the expertise of skilled auditors.

Thermographic Cameras Allow for Efficient Inspection in Running Processes

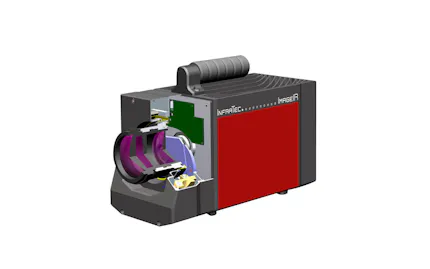

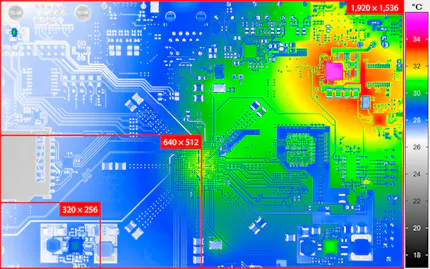

State-of-the-art thermographic cameras of the VarioCAM® High Definition series do not only offer a quick overview on large-scale plants but are also able to reliably capture small defects on photovoltaic modules in detail. Next to the high geometric resolution for this type of application the viewfinder of the infrared camera is of advantage.

The full capacity of photovoltaic modules is generated in the course of a day in direct sunlight. Therewith, the thermographer whose task it is to inspect the modules can work even more efficiently than with a display that is exposed to brightest sunlight. Modern precision telephoto lenses or wide-angle-lenses complete the equipment for this demanding measuring task. Thus, installations of each size can be inspected efficiently and reliably, even from inconvenient points of view. Using the thermographic test system PV-LIT by InfraTec already during production the different types of solar cells and moduls can be checked for the most varied defects.

Fast Reporting of Inspection Results

The easy-to-handle concept of the infrared camera as well as a low maintenance requirement are a big advantage for the user. Especially the VarioCAM® HD inspect series provides a rugged design and excellent handling features for outdoor applications. The thermographic software IRBIS® 3 allows for an efficient reporting of the acquired thermographic data and for generating comprehensive reports in order to assure a clearly structured and complete documentation of the inspection results.

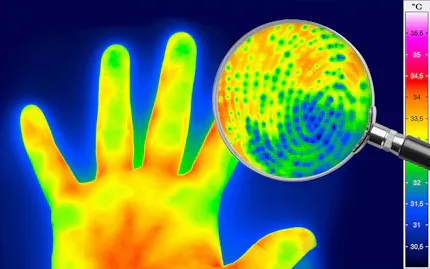

Trained staff for preventing measurement errors and misinterpretations

The use of a infrared camera easily brings a number of "colourful images". Of most importance when analysing thermal images is a profound knowledge about the function of photovoltaic installations as well as about physical regularities. On a regular basis InfraTec offers application-oriented trainings on the inspection of photovoltaic installations with thermographic cameras at its training centre in Dresden.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.