In-process Industrial Temperature Measurement – INDU-SCAN

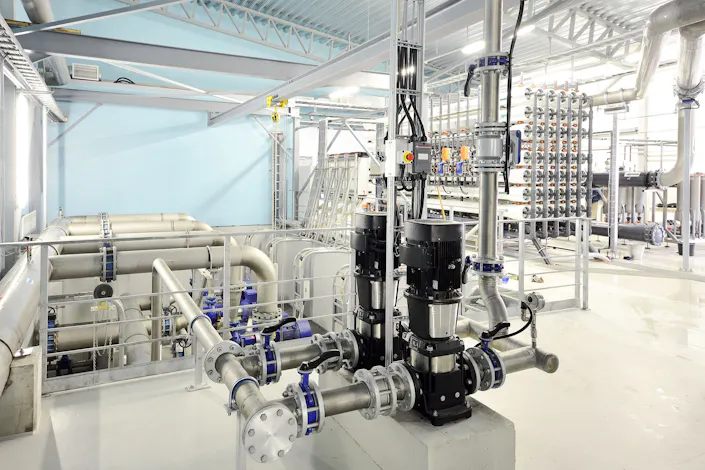

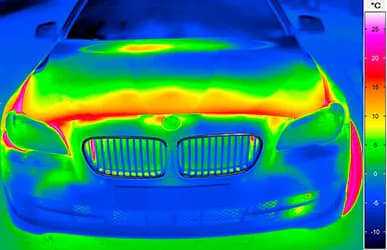

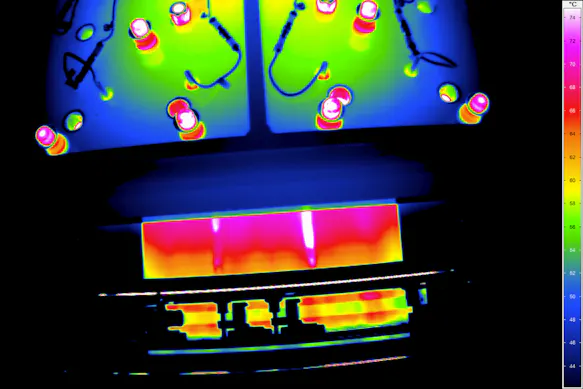

Contactless measurement of temperature distributions and profiles with industrial thermographic cameras permits efficient monitoring and control of temperature-dependent processes and procedures within a system-integrated quality assurance programme in industry.

In-process Temperature Measurement at its Best – INDU-SCAN 4.0

Customised automated thermography solution based on many years of experience and intensive analysis of the respective thermal signatures by our development and application engineers

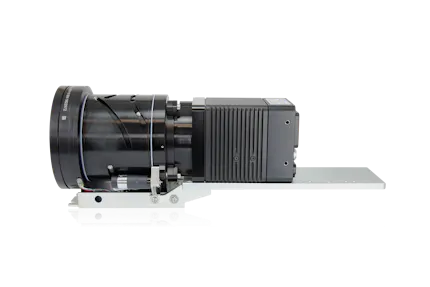

Professional pre-analyses and selection of camera heads and optics according to strict technical measurement criteria of the inspection task ensure correct implementation

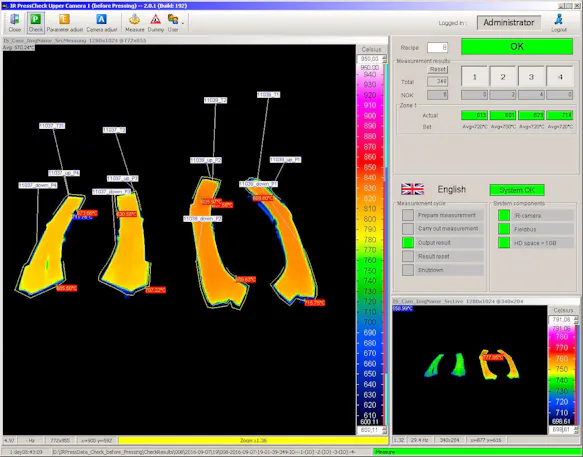

Simultaneous, partly multi-stage multi-spot analyses, transformation and algorithmic handling of nonlinear thermal signatures and heat flows with the most modern software tools, making use of experience-based algorithms

Technical implementation based on a flexible hardware and software kit for fast integration of customer-specific requirements

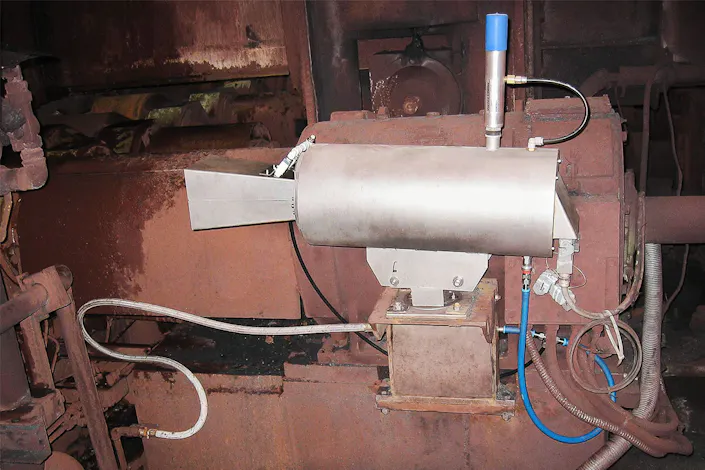

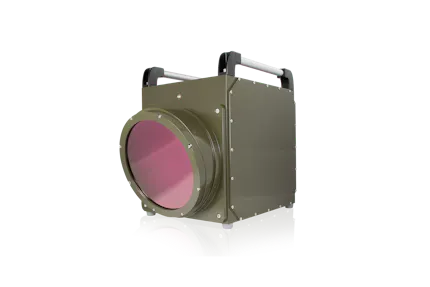

Application of powerful, industrially proved components, that are capable of continuous use

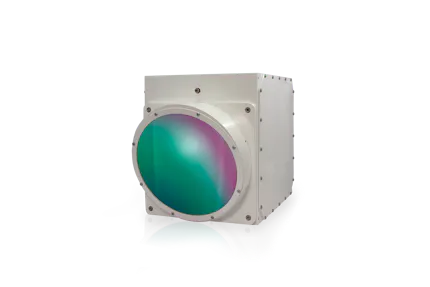

Selection between thermographic cameras of different performance classes and spectral ranges, application-specific protective housings and modular system control units

Individually configurable system software for smooth interaction of all components

Flexible Data Inclusion Thanks to Industry-suitable Interfaces

Data and network management in the era of Industry 4.0 requires flexible and scalable system solutions that can be reliably integrated into plant and machine complexes. The transfer of digital data from cameras to process control INDU-SCAN uses modern interfaces such as GigE / 10 GigE and, if necessary, with increased transfer security or longer distances via fiber optics. The connection to the machine control is done via field bus interfaces like PROFINET, PROFIBUS, CC-Link, Modbus and others. Using TCP/IP protocol, specific quality data can be transmitted for processing and storage in central systems. Storing thermographic and other data in a database allows for a comprehensive evaluation of infrared images and sequences. Furthermore, the database offers an interface for storing the quality data in external database systems. By using these results, you can refine your documentation or based on these results directly control your processes. For this purpose, the measured values are compared in real time with defined threshold and limit values. Depending on the result, an event that has been predetermined by you will then be triggered, for example an alarm.

Comprehensive Service from a Single Source

Complete pre-engineering by InfraTec

Electrical and mechanical engineering (EPLAN, CAD)

System development and documentation

Installation and commissioning on site

Customer-specific system training

Comprehensive, competent and reliable service throughout the entire operating life

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

INDU-SCAN Software Kit, Suitable for Industrial Process Control

Application-specific operating and user interface based on the software kit

Simple integration of even extensive data analyses

Transmission of the measured values

Exact coupling of the image to the process cycle, synchronous use for process control and quality monitoring possible

Recipe management, configurable and editable offline

User management with different security and protection levels

Product Flyer

Get all the information you need at a glance in our product flyers

Use INDU-SCAN for These Industries & Applications

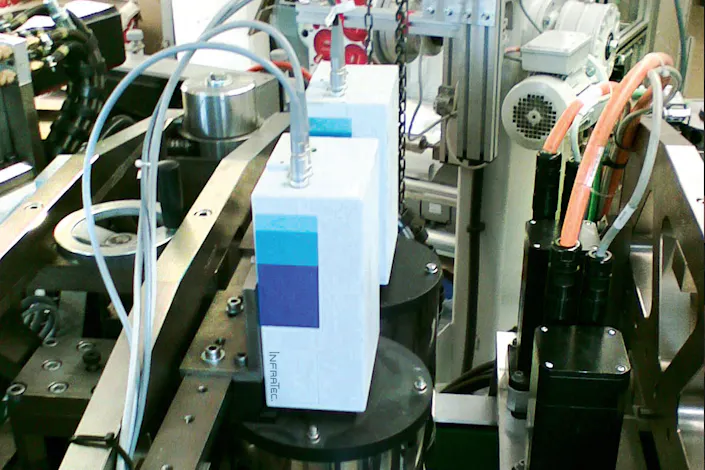

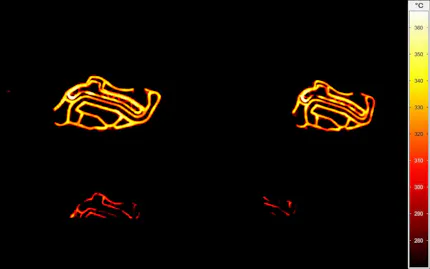

INDU-SCAN in Plastic Welding

With thermography, various processes in plastic welding can be monitored precisely and without contact, e. g. regarding the geometry of the welding zone and material closure. This allows efficient quality control and assurance.

Thermography systems

Enable quality control of the plastic weld seam during the manufacturing process

Detect errors of joining part temperatures

Identify shape/size errors as an indication of just partially joined components

Detect position errors with reference to incorrectly positioned tools and joined parts

Allow conclusions to be drawn about material defects, cavities, inclusions, holes, etc.

Take over the thermal testing in the process cycle

Test and characterise joint connections, e. g. laser welded joints, adhesive joints

Enable adapted signature analysis

Features and capabilities of our thermography solution for plastic welding:

Fast triggered thermographic camera

Adapted recipe creation and processing

Full system integration for series production; remote control and logbook

Industrial control unit