Electronic / Semiconductor Testing Solution - E-LIT

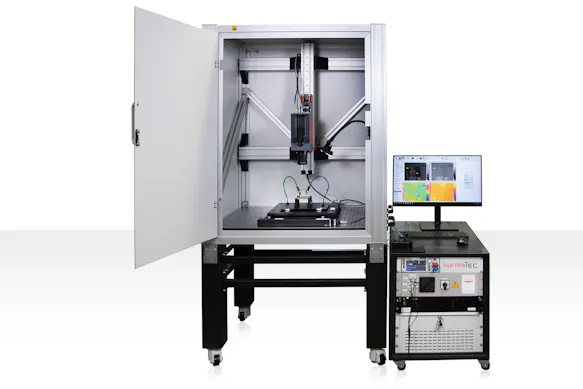

Modular Automated Test Bench

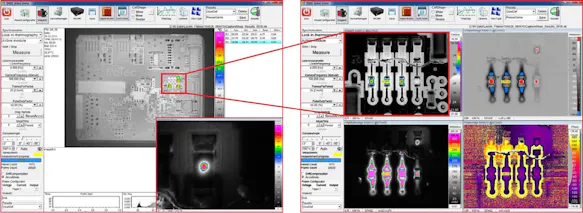

Thermal analysis of electronic and semiconductor devices

Modular test bench for online lock-in measurement

Reliable detection of thermal anomalies in the mK and μK range

Spatial location of defects in multilayer PCBs and multi-chip modules

Use of thermographic systems with cooled and uncooled detectors

Operational software IRBIS® 3 active with comprehensive analysis options in laboratory conditions

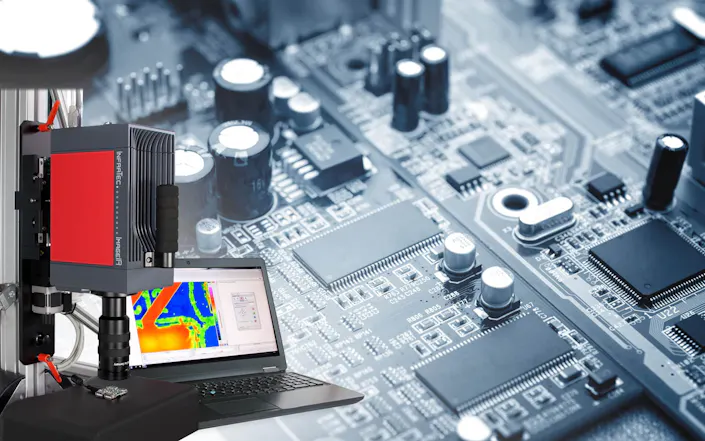

Automated Lock-In measurement with E-LIT from InfraTec

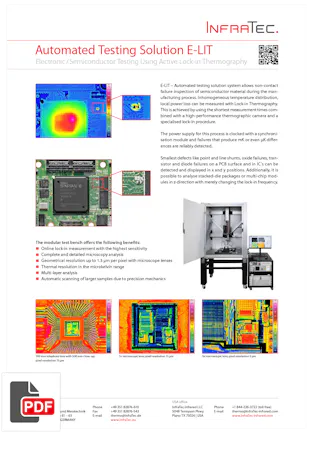

E-LIT – Lock-In Thermography for electronics is an automated testing solution system (as part of NDT techniques) which allows non-contact (electrical) failure analysis of semiconductor material during the manufacturing process. Inhomogeneous temperature distribution, local power loss, leakage currents, resistive vias, cold joints, latch-up effects and soldering issues can be measured with Lock-in Thermography. This is achieved by using the shortest measurement times combined with a high-performance thermographic camera and a specialised lock-in procedure.

The power supply for this process is clocked with a synchronization module and failures that produce mK or even μK temperature differences are reliably detected by the Lock-in Thermography system.

Smallest defects at electronic components like point and line shunts, issues from overheating, internal (ohmic) shorts, oxide defects, transistor and diode failures on a PCB surface, in integrated circuits (IC´s), LED modules and battery cells can be detected and displayed in x and y positions. Additionally, it is possible to analyse stacked-die packages or multi-chip modules in z-direction with merely changing the lock-in frequency.

The powerful Lock-in Thermography software uses the latest algorithms and routines from most recent scientific publications.

E-LIT is extremely powerful also in resolving smallest geometrical structures as it can be equipped with strong microscopic lenses and additional SIL lenses. Identifying smallest structures with InfraTec´s E-LIT does not mean that the resulting field of view will also be smallest – implementing thermal cameras with detector sizes of up to (1,920 x 1,536) pixels provide large scale microscopic imaging. For even larger imaging stitching options are available.

Benefits of the Modular Test Bench

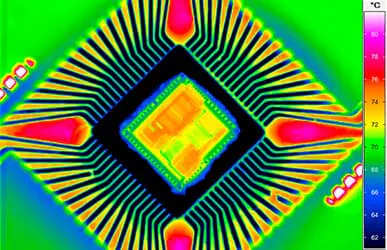

Measurement with one workstation - from the entire circuit board to the smallest detail.

Customised modular measuring station, e. g. with X-Y table and Z-axis manually or motorised adjustable, for positioning and individual adjustment of the working distances, depending on the size of the measured object

Flexibility through variable components, e.g. different optics, holding devices for the test specimen or contacting options

Online lock-in measurement with the highest sensitivity

Complete and detailed microscopy analysis

Geometrical resolution up to 1.3 μm per pixel with microscope lenses

Thermal resolution in the microkelvin range

Multi-layer analysis

Automatic scanning of larger samples due to precision mechanics

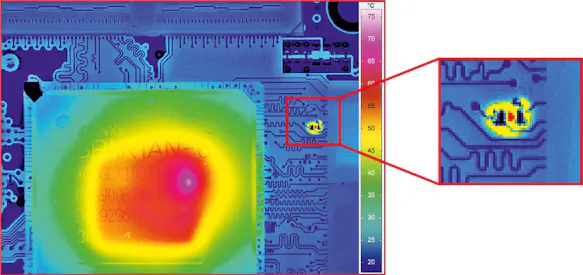

Thermographic Images with Different Optics

Telephoto Lens 100 mm

Microscopic Lens 3×

Microscopic Lens 1×

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

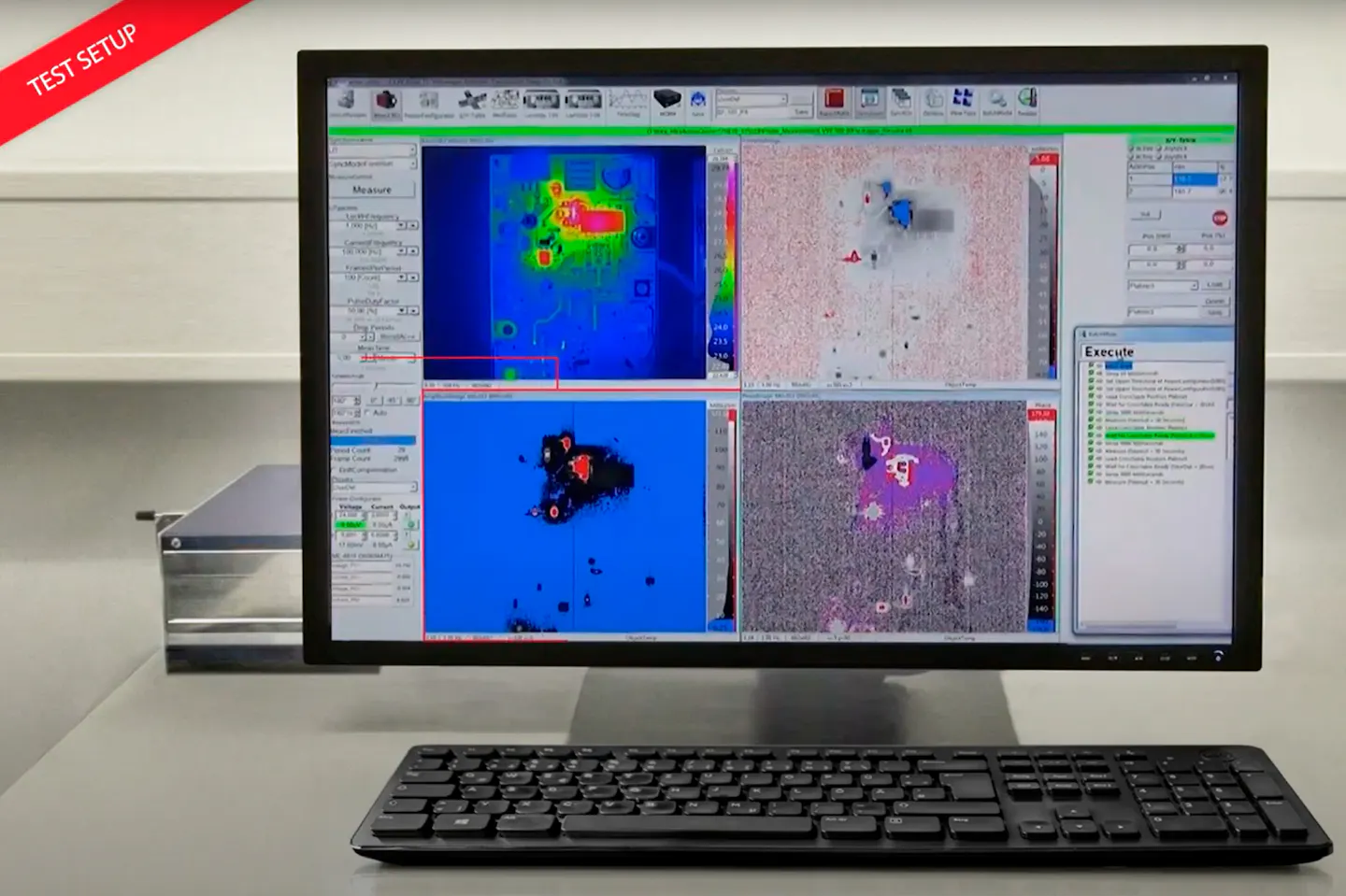

Thermographic Software IRBIS® 3 active

Operational software with comprehensive analysis options in laboratory conditions

Software add-on for automatic error classification based on parameter settings

Intuitive user interface for easy operation

Real-time display of the object being measured in various states

Multifaceted memory options for image data and measurement results

Alternative 0°, 90° or customised set phase angle image for representation of complex intensity information

Merging live and amplitude image

Optional: IV measurement, under sampling, drift compensation, DC-mode, power loss measurement, user and protocol administration, interface preparation: e.g. Profibus, Ethernet

Product Flyer

Get all the information you need at a glance in our product flyers