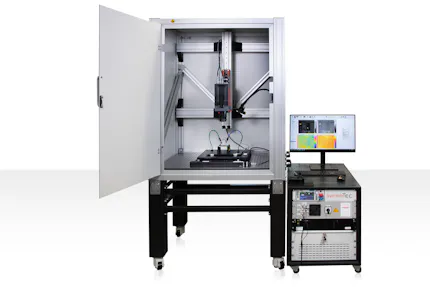

ImageIR® 9400 hp

The high-performance infrared camera ImageIR® 9400 hp from InfraTec is suitable for solving extremely demanding tasks. It impresses with absolute top figures for geometrical, thermal and temporal resolution.

Cooled FPA photon detector with (1,280 × 1,024) IR pixels

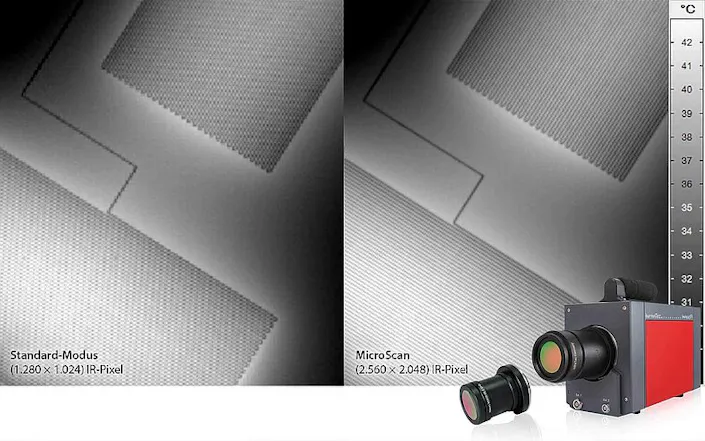

Opto-mechanical MicroScan with (2,560 × 2,048) IR pixels

High-speed mode enabling frame rates up to 622 Hz in full frame

Thermal resolution up to 0.02 K

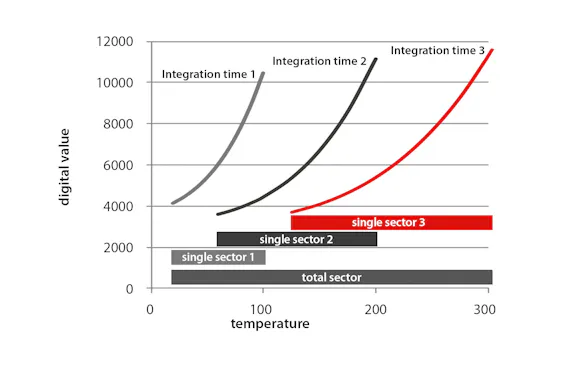

Extremely short integration times in the microsecond range

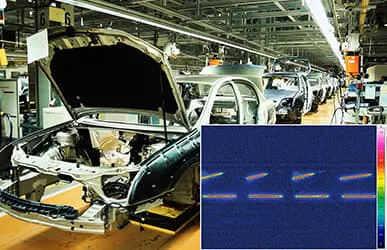

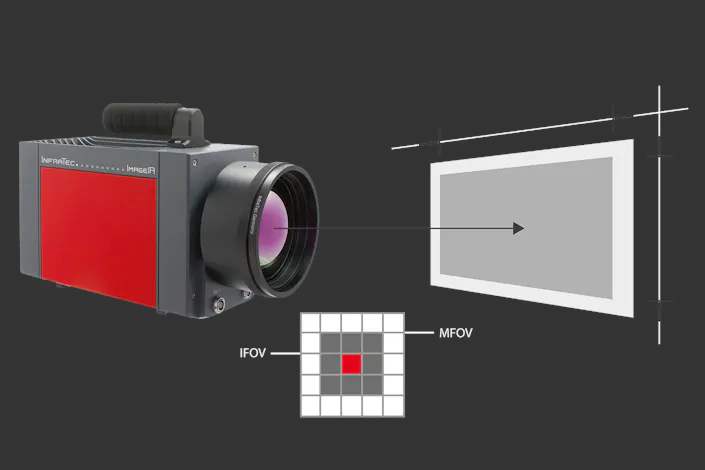

Efficient measurement of smallest structures on large-scale objects

(2.560 × 2.048) IR pixels by genuine camera hardware

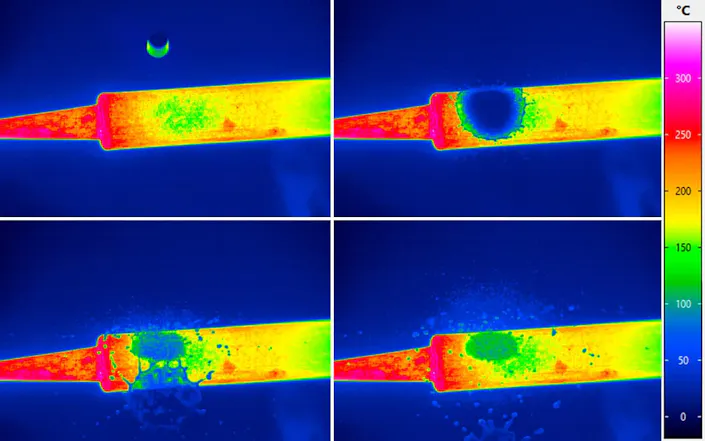

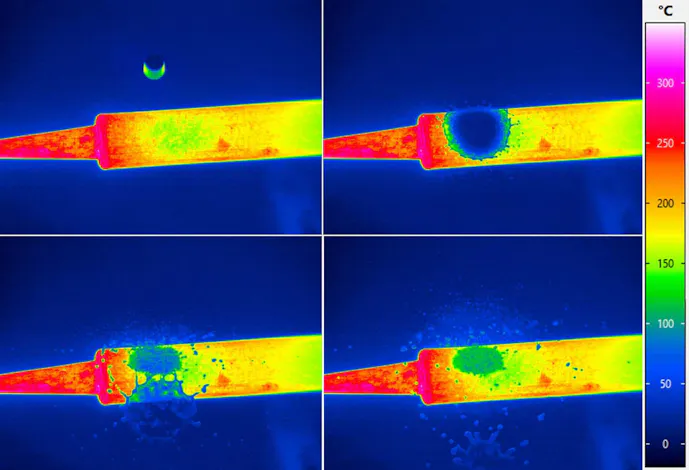

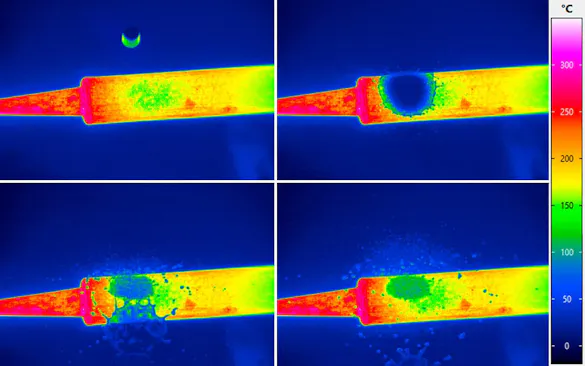

Analysis of extreme temperature changes and gradients in full frame

Highly accurate and repeatable measurements

Precise measurement of smallest temperature differences

High-speed, long-distance interference proof data transmission

Increases frame rates and thermal resolution at the same time using binning technology

Integrated Trigger and Process Interfaces

The camera series ImageIR® is equipped with a snapshot detector as well as with an internal trigger interface, which guarantees a repeatable high-precision triggering. Two respective in- and outputs are used to operate the camera or to generate digital control signals for external devices. Two digital channels of the data stream can be recorded synchronously with those trigger inputs. Additional digital and analogue in- and outputs are available in connection with the process interface IRBIS® 3 process. Furthermore, extra information will be saved directly with the images.

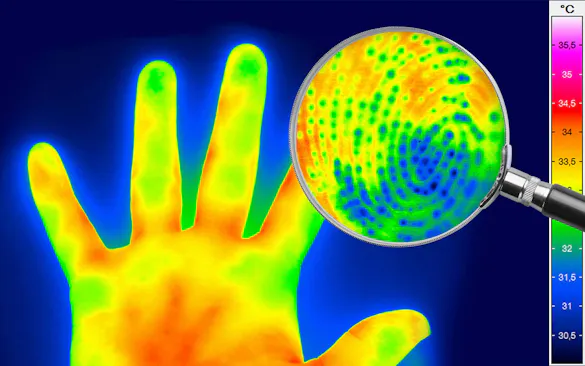

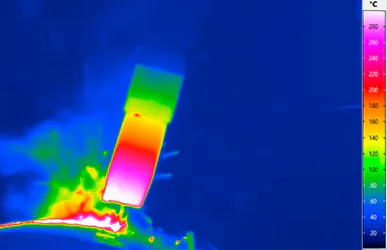

Detect Smallest Temperature Differences Using High Thermal Resolution of 20 mK

The thermal resolution of the ImageIR® infrared camera series allows you to measure smallest temperature differences of (at 30 °C). Thermal images with a narrow temperature span display details absolutely sharp. You will find interesting signatures even there where other infrared camera systems cannot detect any temperature differences any longer.

Take Advantage of the Modular Concept for Your Flexibility

The closed, industrial-suited, high-strength aluminium alloy housing is very compact and protects the sensitive sensors and electronics even during roughest applications. It impresses with its low weight. The modular design allows for an application-specific configuration and later adaptation to varying demands. The interfaces are equipped with push-on connectors to uphold the degree of protection.

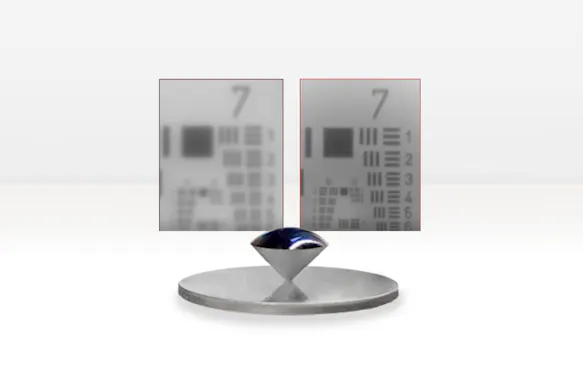

Solid Immersion Lens (SIL) for ImageIR®

In order to make particularly small structures clearly visible, an infrared camera with a large detector format is suitable. In some cases, special measurement and testing tasks require a further increase in spatial resolution. In the field of micro-thermography, high-performance infrared microscopic lenses are used for this purpose. Their benefits can be further increased in conjunction with Solid Immersion Lenses (SIL). Mounted on the optics, these immersion media significantly improve the resolution of even the smallest structures in the µm range.

Maximum Flexibility of the Measurement Options

The infrared camera is equipped with a separate filter and aperture wheel with up to six free positions which allows 30 combinations. A necessity for measurements of high object temperatures and spectral thermography.

Technical Specifications

| Spectral range | (1,.5... 5.5) µm |

| Pitch | 10 µm |

| Detector | InSb |

| Detector format (IR pixels) | (1,280 × 1,024) |

| Image format with opto-mechanical MicroScan (IR pixels) | (2,560 × 2,048) |

| Image recording principle | Snapshot |

| Readout mode | ITR / IWR |

| Aperture | f/2.2 or f/3.0 |

| Detector cooling | Stirling cooler |

| Temperature measuring range | (-40 ... 1,500) °C, up to 3,000 °C* |

| Measurement accuracy | ± 1 °C or ± 1 % |

| Temperature resolution at 30 °C | Better than 0.03 K / 0.02 K in high-speed mode |

| Frame rate | Up to 180 / 342 / 622 / 2,601 Hz; High-speed mode: up to 622 / 1,053 / 1,615 / 3,343 Hz |

| Window mode | Yes |

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

Product Flyer

Get all the information you need at a glance in our product flyers

Do You Want to Know More About the InfraTec Service?

Our experienced service team will be happy to assist you.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.