Photovoltaic Test System - PV-LIT

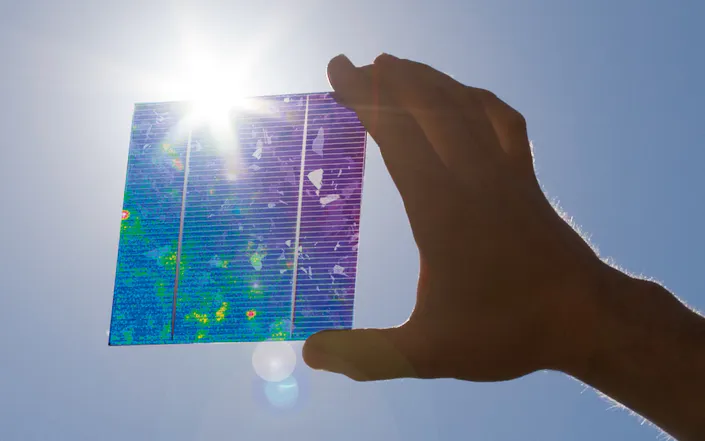

Thermographic solutions ensure high quality of solar cells and modules.

Usable for all types of solar cells and modules (silicon-based or thin-layered)

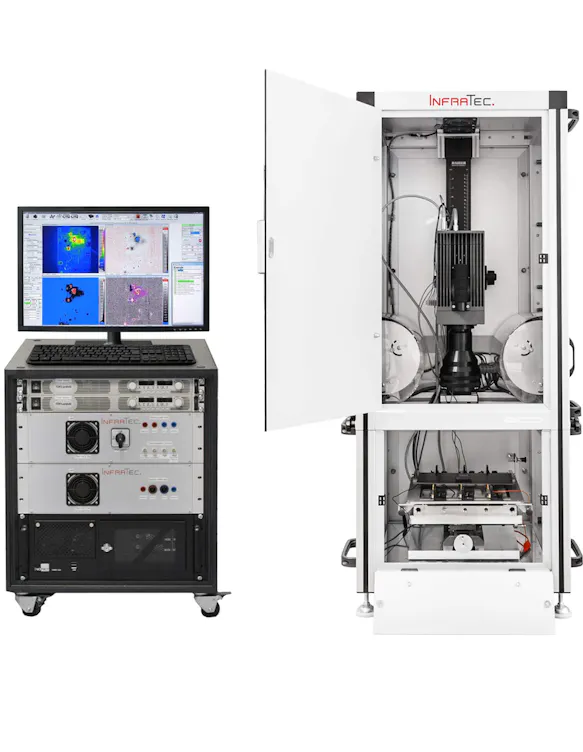

Testing in laboratory

Testing of various solar cells and modules through contact and non-contact measurement

Cell-specific system configuration and determination of test criteria and kind of defects

Flexible Adaption of the System to Types of Cells and Faults Being Tested

The construction of large-area photoelectric solar power plants requires the application of high-performance solar cells and modules of excellent quality. InfraTec's thermographic testing system PV-LIT allows testing for various types of defects – even in the manufacturing process – in different types of solar cells and photovoltaic modules. For example:

Tandem solar cell

III-V solar cell

CIS solar cells

CIGS solar cells

Perovskite solar cells

PERC cells (Passivated emitter rear contact)

Organic solar cells with organic thin film foil to foil process

Solar glass

Smart Glass

Electrochromatic glass

It is also possible to carry out a continuous quality control for serial productions in order to sort defective cells out at an early stage and, following, avoiding additional costs. According to the to-be-tested types of defects, PV-LIT provides the use of contact testing (DLIT) as well as non-contact testing (ILIT).

Further Features

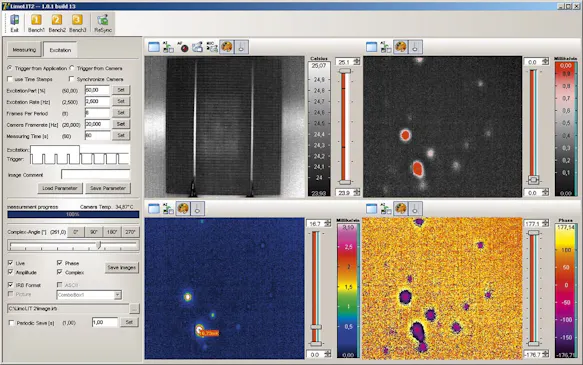

100 Hz online voltage and current measurement, parallel to the lock-in excitation

Sense-line measurement (compensation of voltage drop from the outlet)

Power loss measurement with extended classification of shunts

Timing diagram and export function of voltage-, current and temperature values

Drift compensation

Synchronized zoom the result images

0°/90° phase representation parallel to live and amplitude image

Automated Lock-In measurement with E-LIT from InfraTec

Accurate Representation of Defects with the Help of Lock-In Thermography

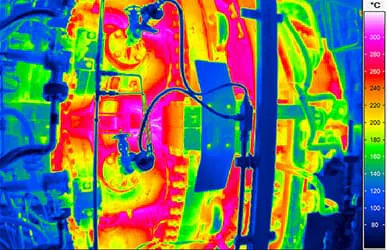

High-performance infrared camera systems with highest thermal resolution of a few hundredths degrees (°C) applied in the PV-LIT system ensure an accurate detection of defects. This is ensued in a precise cooperation of the excitation and evaluation unit. Thus, lock-in thermography can be used by performing a pulsed excitation of solar cells, for instance through LEDs and a triggered image acquisition. By means of this method, defects - even those being below surface - will be detected and clearly displayed as local heating (shunts). Even after thorough infrared quality testing cells as well as modules in running operation can be checked using thermography. Make use of the potential that photovoltaic inspection offers!

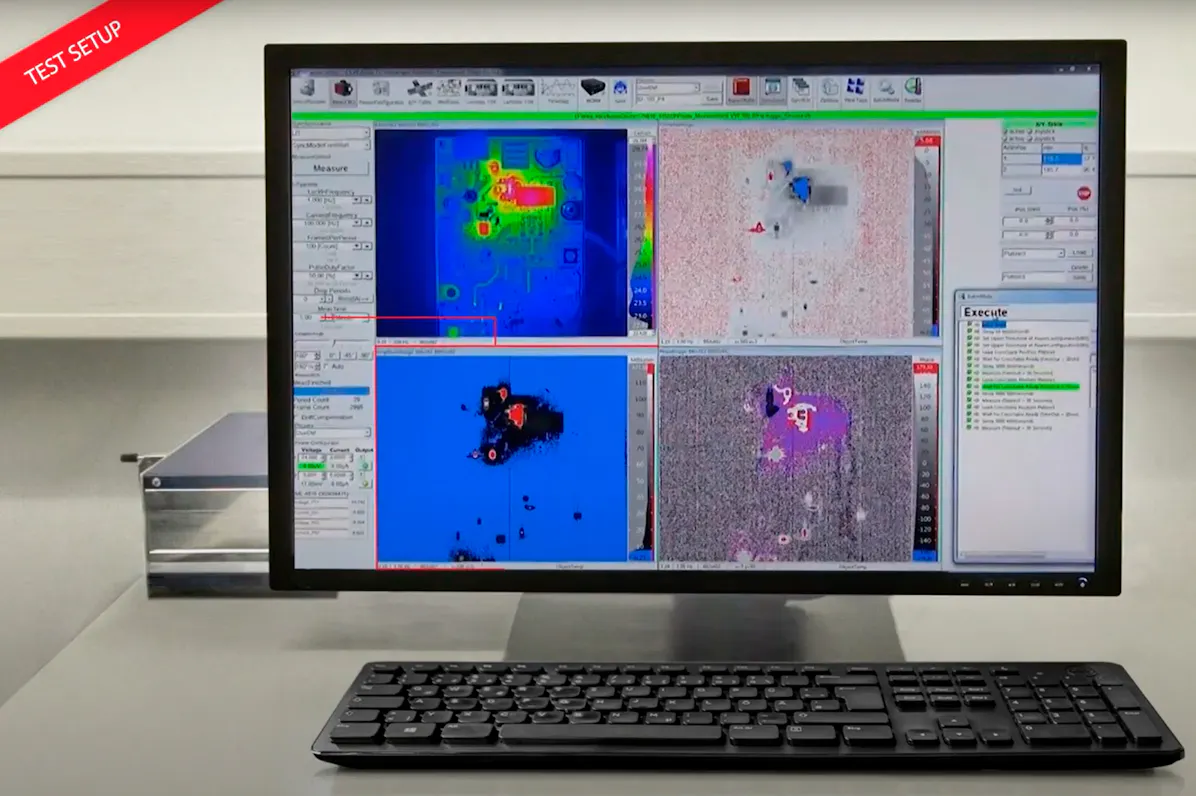

Highly Sophisticated Software for System Control and Evaluation

Apart from the PV-LIT hardware, the system's software does play a decisive role for the detection of defects. It allows the setting of important parameters, such as excitation and exposure frequency or excitation amplitude, and enables the evaluation with various algorithms of active heat flow thermography. Thereby, it is possible to display amplitude images and also freely definable phase images supporting the detection and classification of defects.

Product Flyer

Get all the information you need at a glance in our product flyers