Thermography in Plastics Industry

Wide application range of thermal imaging in plastics industry

Thermography allows specific tempering of injection moulds and deep-drawing

Thin plastic films are highly transparent and require special filters for their measurements

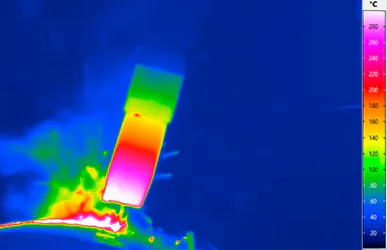

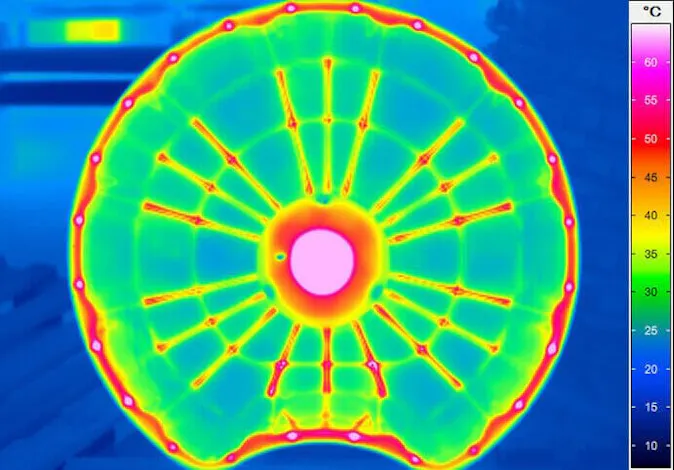

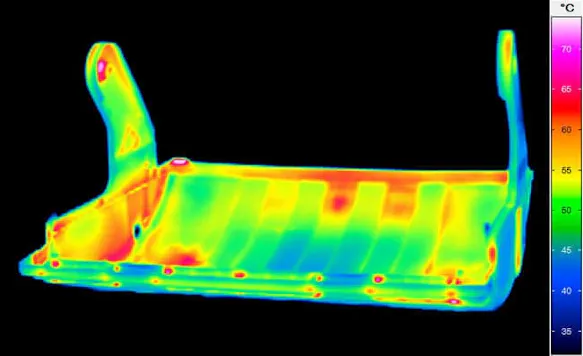

Thermal Optimisation of Moulds

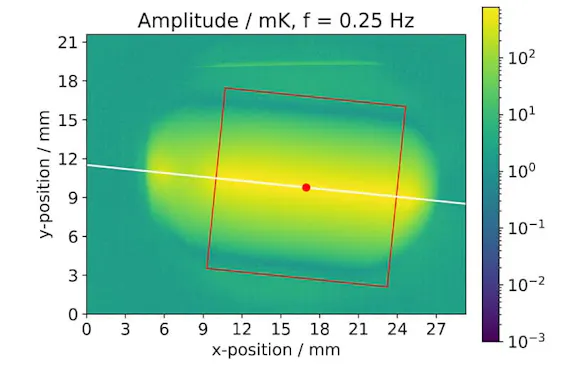

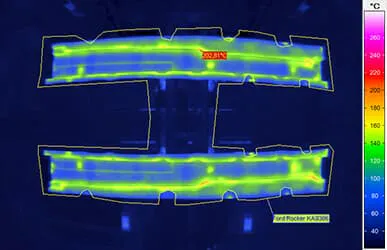

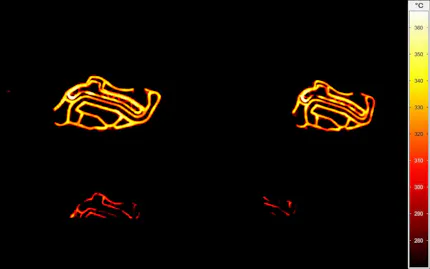

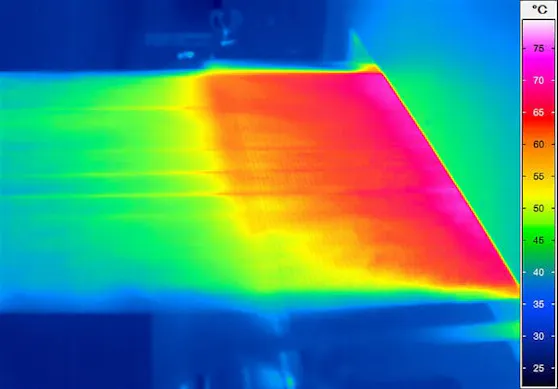

Temperature distribution of plastics in injection moulds and for deep-drawing is a critical aspect for the quality of manufactured moulded bodies. Contacting measurements are just as much extensive as the application of pyrometers. In contrast to that, infrared camera systems offer the advantage to provide a complete picture of moulds or moulded bodies’ temperature distribution. However, moulds consist of metal and, therefore, reflect background radiation.

A thermographic analysis is carried out much easily when measuring the moulded body itself. Attention should be paid to the fact that temperature measurement is ensued immediately after opening the mould and before the moulded form has been put out, so that this new product has hardly cooled down. Thus, the temperature of the mould can be indicative of the moulded result’s temperature.

The high frame rate (of up to 60 Hz) of InfraTec’s camera series VarioCAM® high definition ensures a precise thermal image acquisition at the exact point in time. Moreover, due to the integration of stationary infrared camera systems, such as VarioCAM® HD head, into production processes, it is possible to regulate the mould’s temperature in case of temperature deviations.

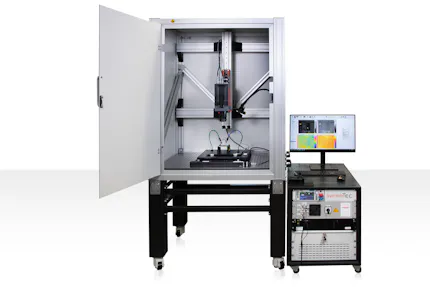

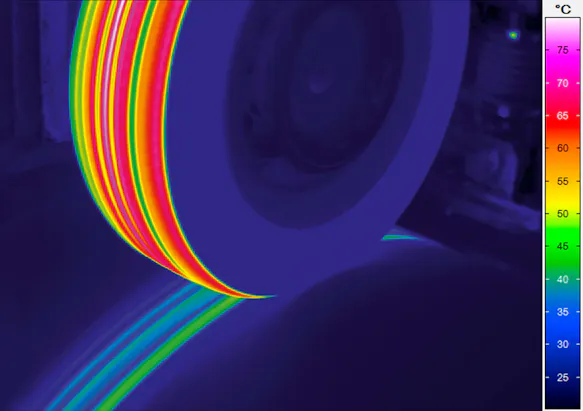

Measurement of Plastic Films by Means of Filtering

Temperature represents an important quality aspect in the manufacturing process of thin plastic films. This measurement can be carried out without any contact by applying infrared camera. Nevertheless, attention should be paid to the high transparency of the plastic films. A solution for this problem is provided by InfraTec’s special infrared camera systems of the camera series ImageIR® which can be equipped with spectral filters and, therefore, are able to filter background radiation out. These infrared camera systems also feature high frame rates of more than 10 KHz, especially for the acquisition of fast extrusion processes accurate in every detail.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.