Events, Trainings and Fair Appointments

As an expert in thermography, we are available for you at numerous exhibitions and events in order to answer your questions and to offer our competent assistance in all infrared thermography matters. Visit our booths and convince yourself of the tremendous benefits, which our thermal camera models and systems have to offer.

In addition to on-site events, we also offer a diverse selection of free online events. In topic-specific, compact presentations, various speakers from the respective specialist areas present the possibilities and special features in the numerous applications.

Our application engineers will be happy to counsel you!

Thermography Events

InfraTec's online events give you the opportunity to learn more about the possibilities of thermography in your demanding field of activity in a concentrated form. Meet colleagues for professional exchange and get to know innovative product news as well as system solutions from InfraTec.

We look forward to your participation.

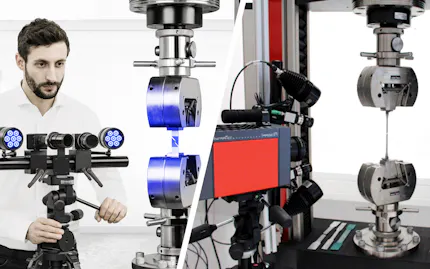

Training: Active Thermography in NDT

InfraTec offers a special seminar "Active Thermography in NDT" for thermography users with a corresponding professional orientation. It facilitates an efficient introduction to this NDT method. It also supports you in assessing for which of your concrete inspection tasks the various methods of active thermography, for example lock-in thermography or pulse-phase thermography, can best be used.

Watch Online Events On Demand

Missed one of our online events? We offer you the possibility to watch some events retrospectively.

To watch an event on demand, we only need some data from you. You will then receive the link to the webinar by e-mail.