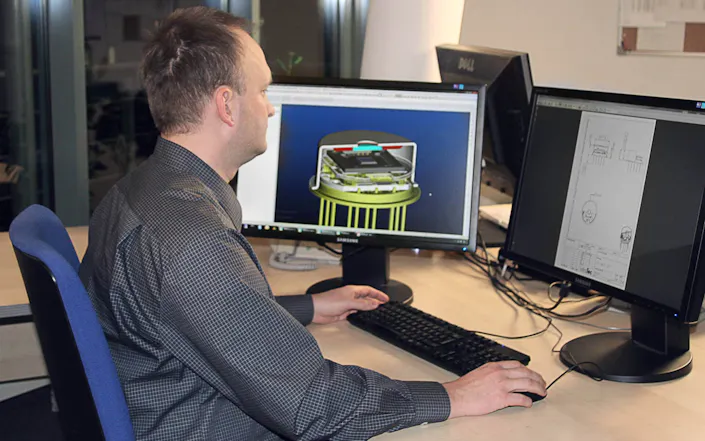

Construction and Design of the Most Modern Infrared Detectors

For more than 30 years, our design team has been working together with the construction department to develop the most modern infrared detectors, their technology and special production equipment. Our modular design system allows for a short design stage, even for demanding solutions outside of our standard programme. Based on 3D-CAD, we can develop infrared detectors from first simulations to the start of production. In addition to daily requests for application assistance, we work on the next generation of pyroelectric detectors.

Detector Production at the Company Headquarters in Dresden

The detector production department has all necessary technologies and equipment along with a 1,600m

Detector Production

Our personnel is familiar with modern techniques of simulation, production and testing as well as with various applications of our infrared detectors. Thus, we produce prototypes, small batches and large quantities with highest quality.

We can guarantee long-term competencies in an ever-changing pyroelectric detector market. High quality also requires good organisation, documentation and investments. These requirements form our core-competencies, which ensure our permanent success in the international market:

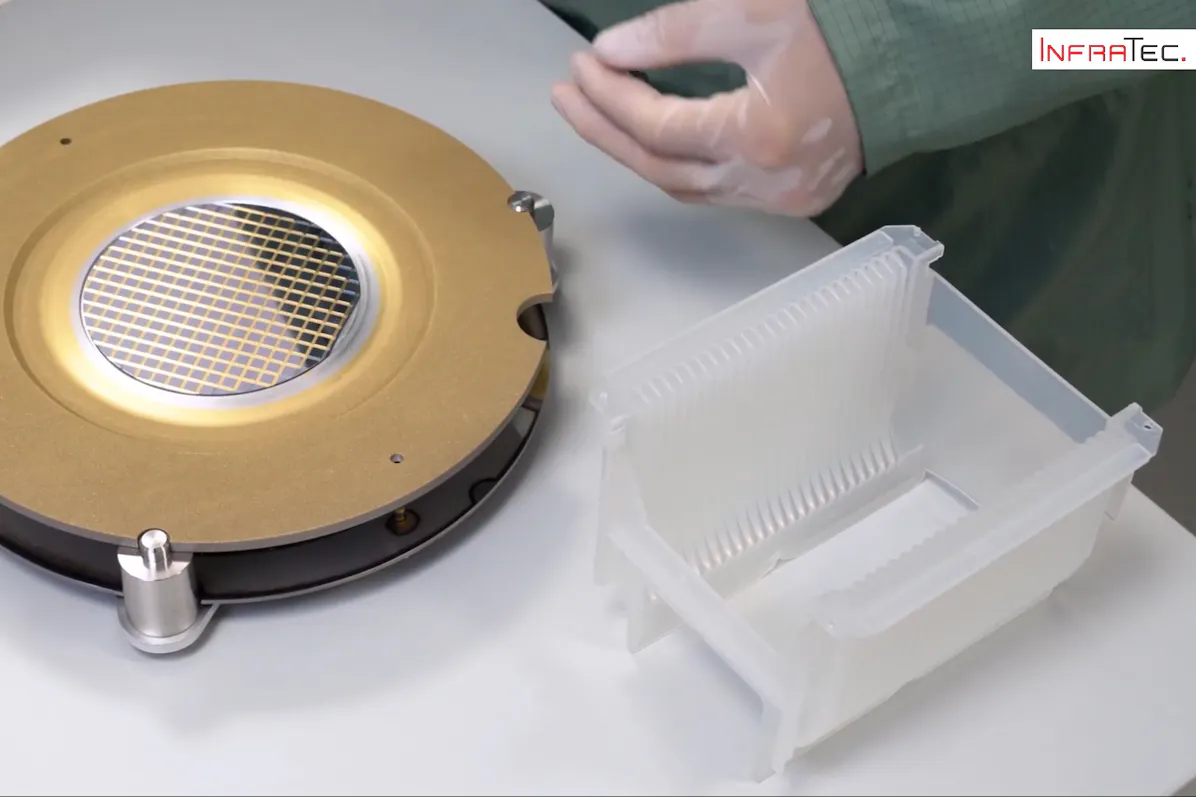

Patterning of Lithium Tantalate Wafers

Crystal characterisation

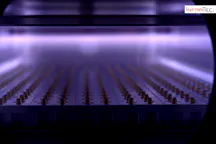

Vacuum coating

Infrared absorbent layer

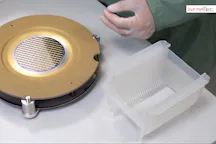

Spectral Measurements of IR Filters, Characterization and Mounting

100% wafer testing for transmittance, blocking and temperature drift

Epoxy adhesive technology for infrared windows and IR filters; soldered windows are available for special applications

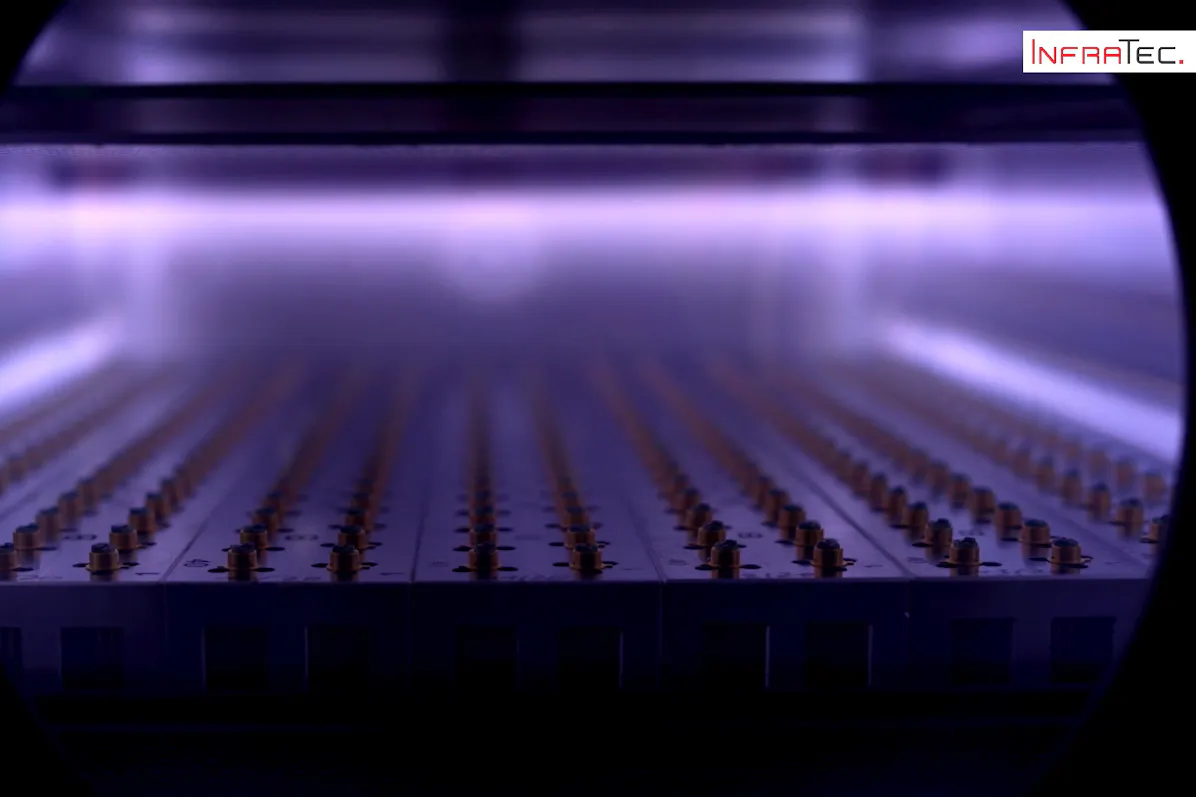

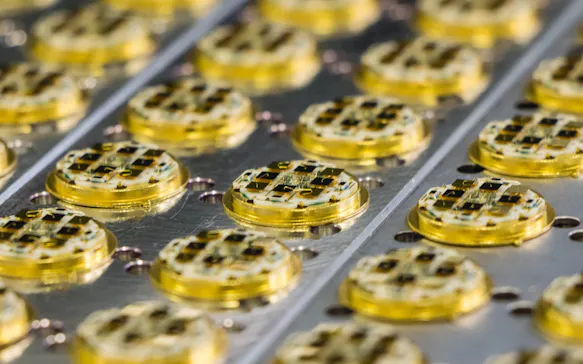

Detector Assembly

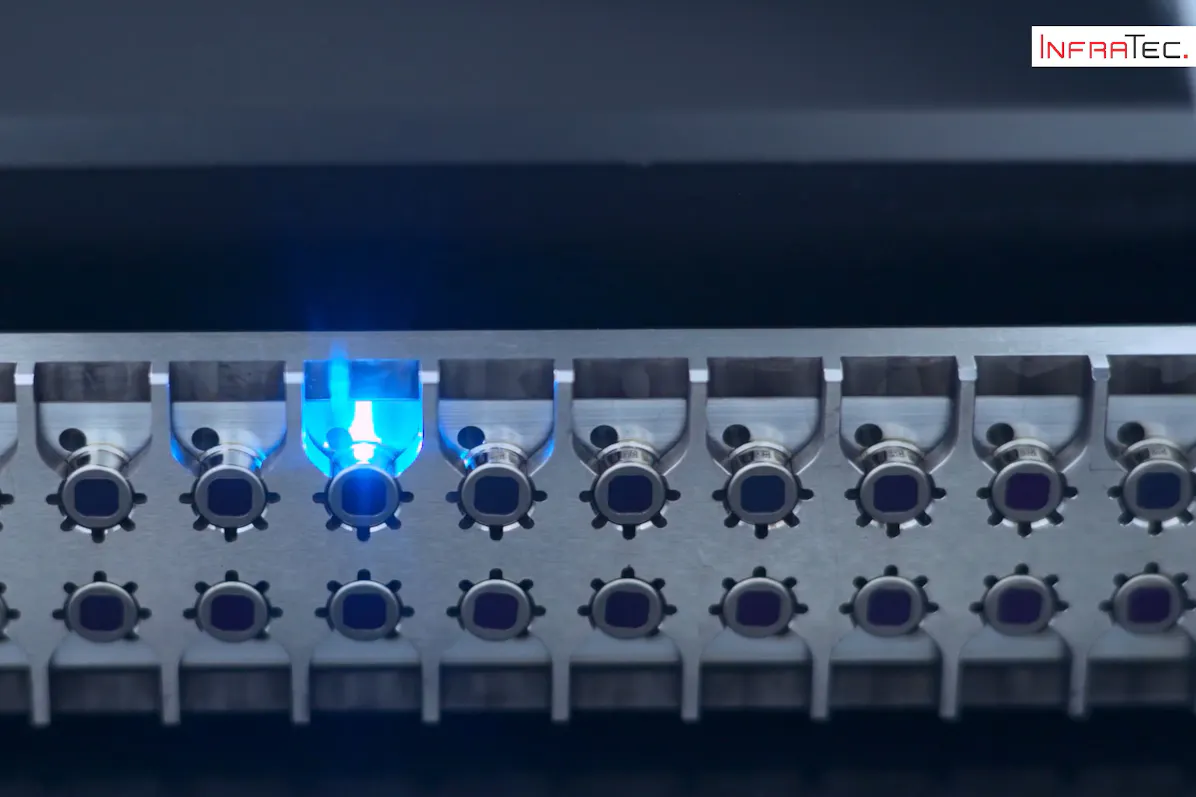

COB in TO metal housings

Gold wire bonding at low temperatures

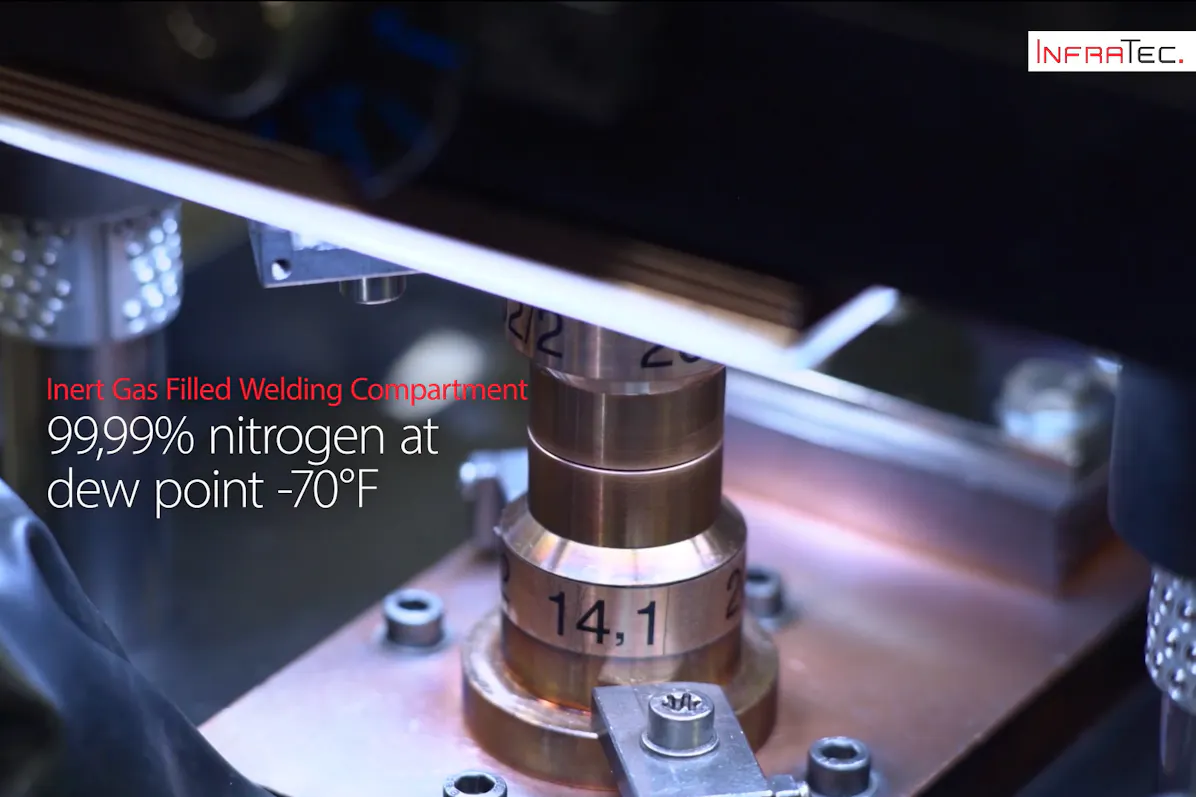

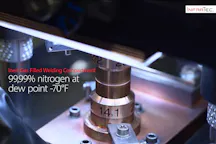

Leak-proof sealing of the housings with 99,99 % N

2

Final Measurements

100 % burn-in testing, including temperature cycling test

100 % gross leak testing

Calibrated measurements for automatic signal- and noise measurements

Guaranteed storage of production data for complete verification of safety-relevant applications

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our experienced engineers, receive further technical information or learn more about our additional services.