Infrared Radiation

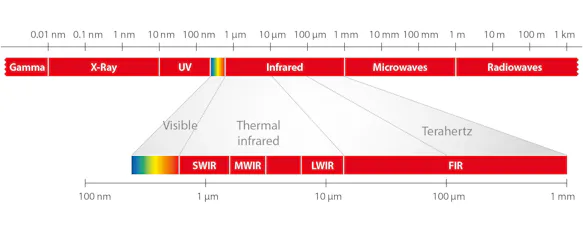

Infrared radiation (IR radiation for short or infrared light) describes electromagnetic waves in the spectral range between visible red light and longer-wave microwave radiation (also known as terahertz radiation). Infrared (IR, infrared light) has wavelengths λ between 780 nm and 1 mm, which corresponds to a frequency range from 300 GHz to 400 THz.

In the second half of the 19th century, it became known that heat radiation and other electromagnetic waves, such as visible light or radio waves, were similar in nature. This was followed by the discovery of the laws of radiation by KIRCHHOFF, STEFAN, BOLTZMANN, WIEN and PLANCK.

Discovery of Infrared Radiation

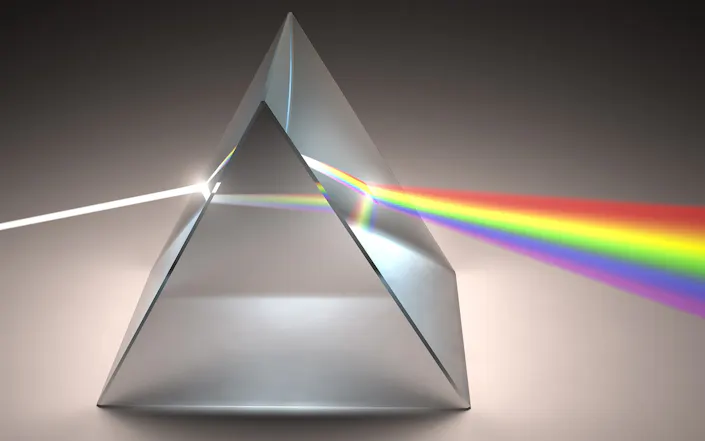

Infrared radiation was discovered around 1800 by Friedrich Wilhelm Herschel while trying to measure the temperature of the different colours of sunlight. For this purpose, he allowed sunlight to pass through a prism and placed thermometers in the individual colour ranges. He noticed that beyond the red end of the visible spectrum, the thermometer displayed the highest temperature. From the observed increase in temperature, he concluded that the solar spectrum continues beyond the visible red light.

Range within the Electromagnetic Spectrum

Infrared radiation is that part of the electromagnetic spectrum that is immediately adjacent to the red light of approx. 760 nm on the long-wave side of the visible spectrum and extends to a wavelength of approx. 1 mm.

In this respect, the wavelength range of up to approx. 20 µm is of importance to technical temperature measuring.

Subdivision of Infrared Spectral Range

| Description | German abbrevation |

English abbrevation |

Abbrevation according to CIE or DIN |

Wavelength /µm |

| Near-infrared | NIR | NIR | IR-A | 0.78 ... 1.4 |

| Shortwave-infrared | NIR | SWIR | IR-B | 1.4 ... 3.0 |

| Midwave-infrared | MIR | MWIR | IR-C | 3.0 ... 8.0 |

| Longwave-infrared | MIR | LWIR | IR-C | 8.0 ... 15.0 (50.0) |

| Far-infrared | FIR | FIR | IR-C | 15.0 (50.0) ... 1,000.0 |

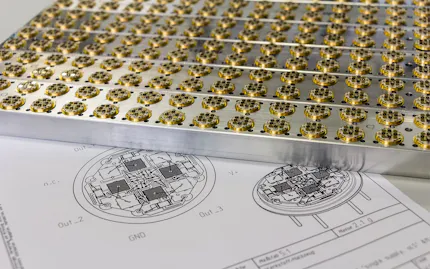

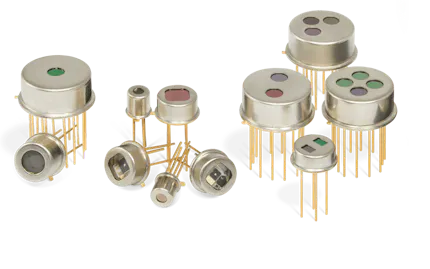

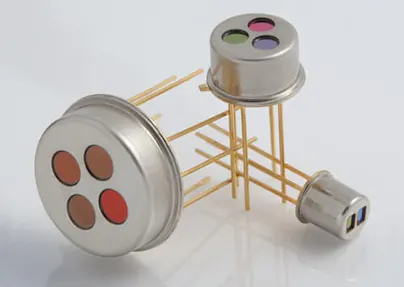

Infrared Radiation in Sensor Technology

Pyroelectric detectors from InfraTec utilise their strengths in measurement technology particularly in the mid-infrared range, but can also be used for laser applications in UV as well as in the range of distant infrared radiation.

The absorption bands of numerous gases lie in the mid-infrared range from 2.5 to 13 µm. The concentrations of gases such as CO

By recognizing typical gas emissions in the MIR, which arise in the event of a fire, flames can be recognized selectively and very safely over long distances (flame detector, triple IR, IR3).

Classification of the infrared spectral range into bands is not clearly defined. The technical applications of NDIR gas analysis, flame spectroscopy and pyrometry often use the subdivision of NIR, SWIR, MWIR, LWIR and FIR. The CIE (International Commission on Illumination) and DIN 5031-7 propose a division into bands IR-A, IR-B and IR-C.

Infrared Radiation in Thermography

The principle of infrared thermography is based on the physical phenomenon that any body of a temperature above absolute zero (-273.15 °C) emits electromagnetic radiation. There is clear correlation between the surface of a body and the intensity and spectral composition of its emitted radiation. By determining its radiation intensity, the temperature of an object can thereby be determined in a non-contact way. This is based on a number of physical parameters.

The precondition for a reliable temperature measurement is the use of the right infrared camera. As a specialist for thermography, InfraTec offers a complete range of different thermal imaging cameras for professional, universal use.

Contact-free measurements of temperature spreads on object surfaces or of processes provide information about the progression of the process or the state of the object. Since thermography is an image-generating process, deviations from the standard, for example, can be detected immediately. This is essential, as even the smallest discrepancies can have a significant impact on functionality and quality.

Sources of Infrared Radiation

Sources of infrared radiation are initially all objects, whereby their temperature is the most important parameter (temperature radiator, Planck's law of radiation). This is used in contactless temperature measurement, pyrometry. Intensity and spectral distribution also depend on the surface of the object, which is described with the emission factor. An ideal temperature radiator has a spectrally constant emission factor of 1 and is referred to as a black radiator. Commercially available radiators are mostly not black at all, but have an electrically heated cavity that allows the radiation to escape through a perforated screen. Physically, such a cavity is almost ideally "black", since it does not reflect any radiation (cavity radiation). Technically, however, it is easier to manufacture and also has much more long-term stability than an ideal black surface. Light bulbs are also thermal radiators. However, their upper wavelength is limited to about 4 µm due to the absorption of the glass bulb. Other sources of infrared radiation are LEDs and lasers. Their spectrum is usually limited to a small range that depends on the semiconductor material.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our experienced engineers, receive further technical information or learn more about our additional services.